Ежеднево

Поставщик решений для очистки воды One-Stop

- Главная

- Почему Snowate

- Запчасти

-

Насос высокого давления опреснения

-

Насос CNP

-

Модуль EDI

-

Мембраны

-

Ионообменные смолы

-

Химикаты обработки воды

-

Корпус фильтра точности/безопасности

-

Корпус фильтра Само-чистки

-

Еда & фармацевтический корпус фильтра

-

Патроны фильтра

-

Фильтровальные мешки

-

Термопластичные клапаны

-

Металлический клапан

-

Супмеа Инструмент

-

Инструмент CREATEC

-

Манометр

-

Соленоидный клапан

-

Расходомер

-

SEKO Дозирующий насос

-

Snowate Дозирующий насос

-

Пластиковые клапаны & фитинги

-

УФ стерилизатор воды

-

Генератор озона

-

Промышленный генератор озона

-

Хлорированные дезинфекции оборудование

-

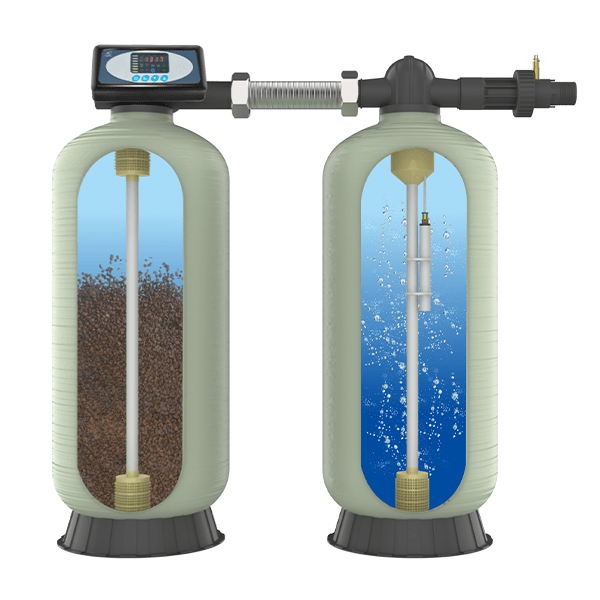

Многопортовые клапаны управления

-

Резервуары FRP

-

Корпуса мембран

-

Фитинги стыковой сварки

-

Трубопроводная арматура

-

Регулятор давления насоса

-

Автоматизация управления

-

Очистка сточных вод

-

- Системы

- Промышленность

- Решение

- Знания & Калькулятор

- Ресурсы

- Контакт