45° short radius butt weld elbow

Butt weld elbow is commonly used fitting in piping systems. It has a curved shape and can bend the pipe in a horizontal or vertical direction. It is connected to the pipe through welding, allowing the fluid or gas to flow along a specific path. It can be used to avoid obstacles, pass through walls or floors, and adapt to different spatial limitations and engineering requirements, achieving flexibility in pipe layout and optimizing the design of the piping system.

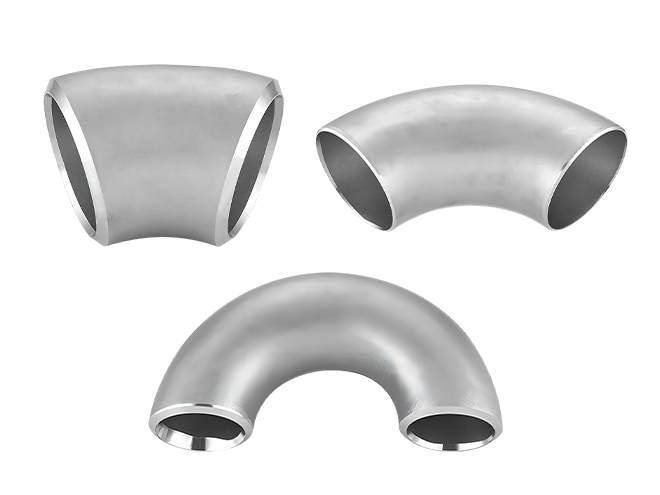

45° butt weld elbow

90° butt weld elbow

180° butt weld elbow

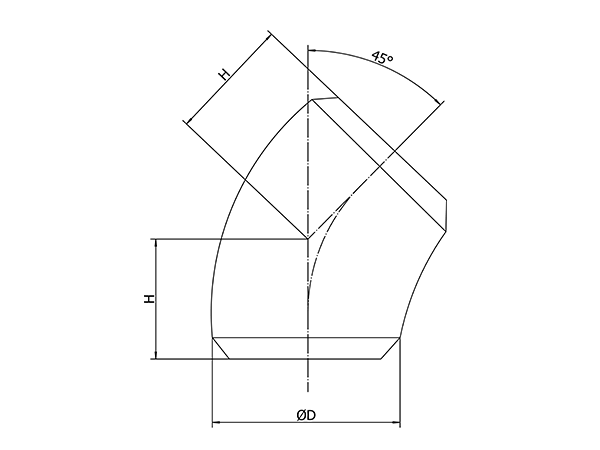

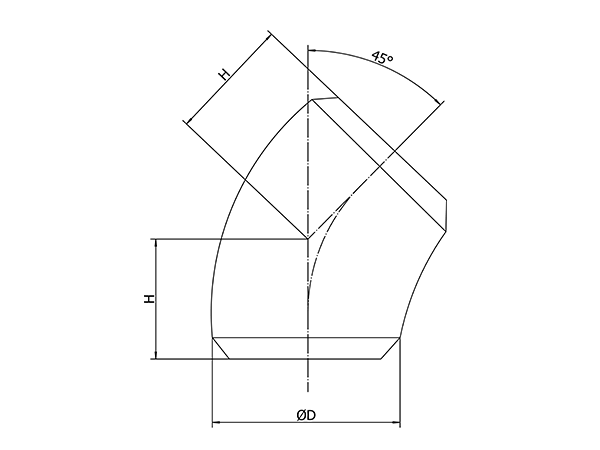

Installation Dimensional Drawing

45° short radius butt weld elbow

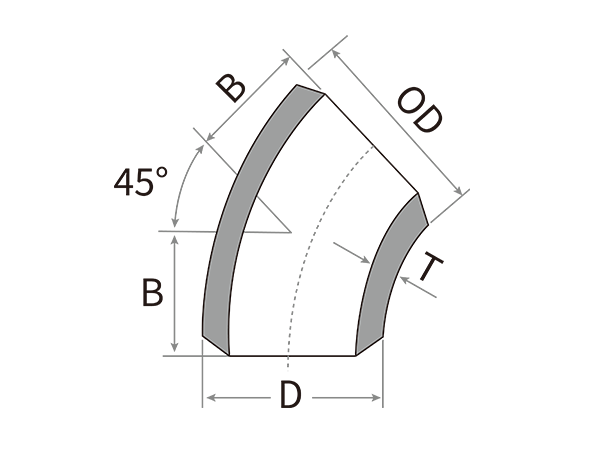

45° long radius butt weld elbow

Specifications

| Nominal Diameter | Outer Diameter D (mm) | Distance from Center to End Face H (mm) | |

|---|---|---|---|

| DN | NPS | ||

| 15 | 1/2 | 21.7 | – |

| 20 | 3/4 | 27.2 | – |

| 25 | 1 | 34.0 | – |

| 32 | 1-1/4 | 42.7 | – |

| 40 | 1-1/2 | 48.6 | 15.8 |

| 50 | 2 | 60.5 | 21.0 |

| 65 | 2-1/2 | 76.3 | 26.3 |

| 80 | 3 | 89.1 | 31.6 |

| 90 | 3-1/2 | 101.6 | 36.8 |

| 100 | 4 | 114.3 | 42.1 |

| 125 | 5 | 139.8 | 52.6 |

| 150 | 6 | 165.2 | 63.1 |

| 200 | 8 | 216.3 | 84.2 |

| 250 | 10 | 267.4 | 105.2 |

| 300 | 12 | 318.5 | 126.2 |

| 350 | 14 | 355.6 | 147.3 |

| 400 | 16 | 406.4 | 168.3 |

| 450 | 18 | 457.2 | 189.4 |

| 500 | 20 | 508.0 | 210.4 |

| 550 | 22 | 558.8 | 231.5 |

| 600 | 24 | 609.6 | 252.5 |

| 650 | 26 | 660.4 | 273.5 |

| 700 | 28 | 711.2 | 294.6 |

| 750 | 30 | 762.0 | 315.6 |

| 800 | 32 | 812.8 | 336.7 |

| 850 | 34 | 863.6 | 357.7 |

| 900 | 36 | 914.4 | 378.7 |

| 950 | 38 | 965.2 | 399.8 |

| 1000 | 40 | 1016.0 | 420.8 |

| 1050 | 42 | 1066.8 | 441.9 |

| 1100 | 44 | 1117.6 | 462.9 |

| Nominal Diameter | Outer Diameter D (mm) | Distance from Center to End Face H (mm) | |

|---|---|---|---|

| DN | NPS | ||

| 15 | 1/2 | 18 | 16 |

| 21.3 | |||

| 20 | 3/4 | 25 | 19 |

| 26.7 | |||

| 25 | 1 | 32 | 22 |

| 33.4 | |||

| 32 | 1-1/4 | 38 | 25 |

| 42.2 | |||

| 40 | 1-1/2 | 45 48.3 |

29 |

| 50 | 2 | 57 | 35 |

| 60.3 | |||

| 65 | 2-1/2 | 76 | 44 |

| 73 | |||

| 80 | 3 | 89 | 51 |

| 90 | 3-1/2 | 101.6 | 57 |

| 100 | 4 | 108 | 64 |

| 114 | |||

| 125 | 5 | 133 | 79 |

| 141.3 | |||

| 139.7 | |||

| 150 | 6 | 168.3 | 95 |

| 159 | |||

| 165 | |||

| 200 | 8 | 219 | 127 |

| 216 | |||

| 250 | 10 | 273 | 159 |

| 267.4 | |||

| 300 | 12 | 325 | 190 |

| 323.9 | |||

| 318 | |||

| 350 | 14 | 377 | 222 |

| 355.6 | |||

| 400 | 16 | 426 406.4 |

254 |

| 450 | 18 | 478 | 286 |

| 457.2 | |||

| 500 | 20 | 529 | 318 |

| 508 | |||

| 550 | 22 | 559 | 343 |

| 600 | 24 | 630 | 381 |

| 610 | |||

| 650 | 26 | 660 | 406 |

| 700 | 28 | 720 | 438 |

| 711 | |||

| 750 | 30 | 762 | 470 |

| 800 | 32 | 820 | 502 |

| 813 | |||

| 850 | 34 | 864 | 533 |

| 900 | 36 | 920 | 565 |

| 914 | |||

| 950 | 38 | 965 | 600 |

| 1000 | 40 | 1016 | 632 |

| 1020 | |||

| 1050 | 42 | 1067 | 660 |

| 1100 | 44 | 1118 | 695 |

| 1120 | |||

| 1150 | 46 | 1168 | 727 |

| 1200 | 48 | 1220 | 759 |

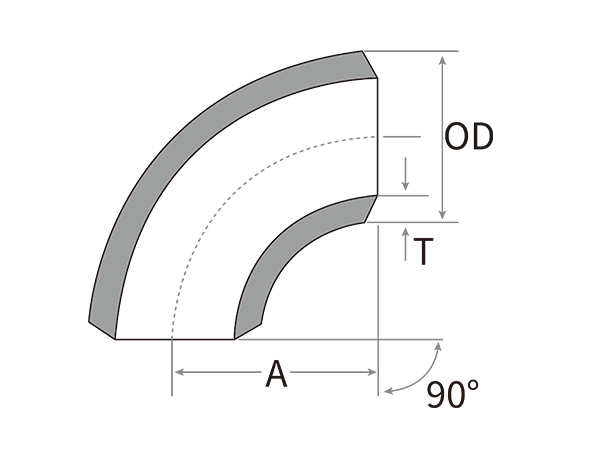

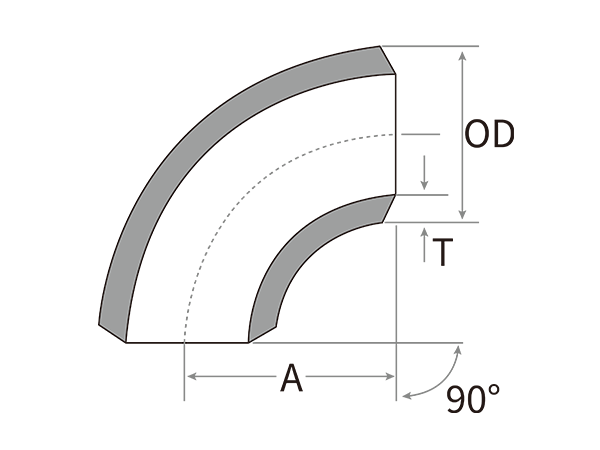

Installation Dimensional Drawing

90° short radius butt weld elbow

90° short radius butt weld elbow

Specifications

| Nominal Diameter | Outer Diameter (mm) | Distance from Center to End Face (mm) | |

|---|---|---|---|

| DN | NPS | OD | A |

| 25 | 1 | 32 | 25 |

| 33.4 | |||

| 32 | 1-1/4 | 38 | 32 |

| 42.2 | |||

| 40 | 1-1/2 | 45 | 38 |

| 48.3 | |||

| 50 | 2 | 57 | 51 |

| 60.3 | |||

| 65 | 2-1/2 | 76 | 64 |

| 73 | |||

| 80 | 3 | 89 | 76 |

| 90 | 3-1/2 | 101.6 | 89 |

| 100 | 4 | 108 | 102 |

| 114 | |||

| 125 | 5 | 133 | 127 |

| 141.3 | |||

| 139.7 | |||

| 150 | 6 | 168.3 | 152 |

| 159 | |||

| 165 | |||

| 200 | 8 | 219 | 203 |

| 216 | |||

| 250 | 10 | 273 | 254 |

| 267.4 | |||

| 300 | 12 | 325 | 305 |

| 323.9 | |||

| 318 | |||

| 350 | 14 | 377 | 356 |

| 355.6 | |||

| 400 | 16 | 426 | 406 |

| 406.4 | |||

| 450 | 18 | 478 | 457 |

| 457.2 | |||

| 500 | 20 | 529 | 508 |

| 508 | |||

| 550 | 22 | 559 | 559 |

| 600 | 24 | 630 | 610 |

| 610 | |||

| 650 | 26 | 660 | 660 |

| 700 | 28 | 720 | 711 |

| 711 | |||

| 750 | 30 | 762 | 762 |

| 800 | 32 | 820 | 813 |

| 813 | |||

| 850 | 34 | 864 | 864 |

| 900 | 36 | 920 | 914 |

| 914 | |||

| 950 | 38 | 956 | 965 |

| 1000 | 40 | 1016 | 1016 |

| 1020 | |||

| 1050 | 42 | 1067 | 1067 |

| 1100 | 44 | 1118 | 1118 |

| 1120 | |||

| 1150 | 46 | 1168 | 1168 |

| 1200 | 48 | 1220 | 1220 |

| Nominal Diameter | Outer Diameter (mm) | Distance from Center to End Face (mm) | |

|---|---|---|---|

| DN | NPS | OD | A |

| 15 | 1/2 | 18 | 38 |

| 21.3 | |||

| 20 | 3/4 | 25 | 38 |

| 26.7 | |||

| 25 | 1 | 32 | 38 |

| 33.4 | |||

| 32 | 1-1/4 | 38 | 48 |

| 42.2 | |||

| 40 | 1-1/2 | 45 | 57 |

| 48.3 | |||

| 50 | 2 | 57 | 76 |

| 60.3 | |||

| 65 | 2-1/2 | 76 | 95 |

| 73 | |||

| 80 | 3 | 89 | 114 |

| 90 | 3-1/2 | 101.6 | 133 |

| 100 | 4 | 108 | 152 |

| 114 | |||

| 125 | 5 | 133 | 190 |

| 141.3 | |||

| 139.7 | |||

| 150 | 6 | 168.3 | 229 |

| 159 | |||

| 165 | |||

| 200 | 8 | 219 | 305 |

| 216 | |||

| 250 | 10 | 273 | 381 |

| 267.4 | |||

| 300 | 12 | 325 | 457 |

| 323.9 | |||

| 318 | |||

| 350 | 14 | 377 | 533 |

| 355.6 | |||

| 400 | 16 | 426 406.4 |

610 |

| 450 | 18 | 478 | 686 |

| 457.2 | |||

| 500 | 20 | 529 | 762 |

| 508 | |||

| 550 | 22 | 559 | 838 |

| 600 | 24 | 630 | 914 |

| 610 | |||

| 650 | 26 | 660 | 991 |

| 700 | 28 | 720 | 1067 |

| 711 | |||

| 750 | 30 | 762 | 1143 |

| 800 | 32 | 820 | 1219 |

| 813 | |||

| 850 | 34 | 864 | 1295 |

| 900 | 36 | 920 | 1372 |

| 914 | |||

| 950 | 38 | 965 | 1448 |

| 1000 | 40 | 1016 | 1524 |

| 1020 | |||

| 1050 | 42 | 1067 | 1600 |

| 1100 | 44 | 1118 | 1676 |

| 1120 | |||

| 1150 | 46 | 1168 | 1753 |

| 1200 | 48 | 1220 | 1829 |

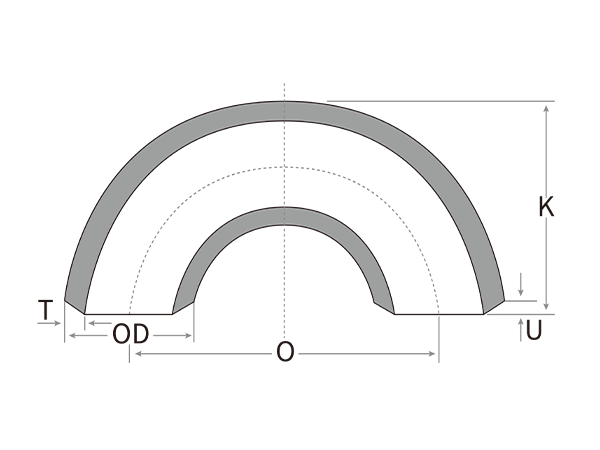

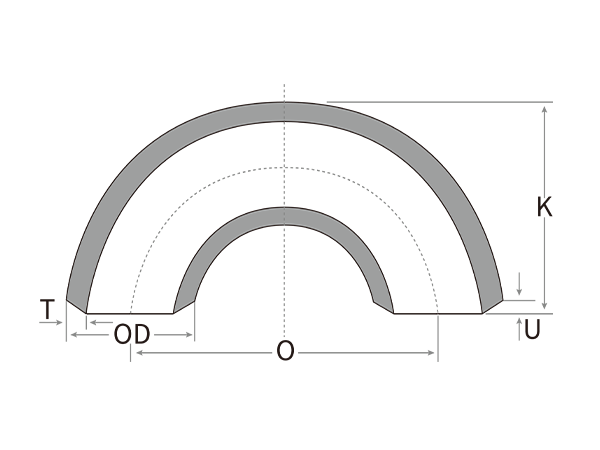

Installation Dimensional Drawing

180° short radius butt weld elbow

180° long radius butt weld elbow

Specifications

| Nominal Diameter | Outer Diameter (mm) | Distance from Center to Center (mm) | |

|---|---|---|---|

| DN | NPS | OD | O |

| 25 | 1 | 32 | 50 |

| 33.4 | |||

| 32 | 1-1/4 | 38 | 64 |

| 42.2 | |||

| 40 | 1-1/2 | 45 | 76 |

| 48.3 | |||

| 50 | 2 | 57 | 102 |

| 60.3 | |||

| 65 | 2-1/2 | 76 | 128 |

| 73 | |||

| 80 | 3 | 89 | 152 |

| 90 | 3-1/2 | 101.6 | 178 |

| 100 | 4 | 108 | 204 |

| 114 | |||

| 125 | 5 | 133 | 254 |

| 141.3 | |||

| 139.7 | |||

| 150 | 6 | 168.3 | 304 |

| 159 | |||

| 165 | |||

| 200 | 8 | 219 | 406 |

| 216 | |||

| 250 | 10 | 273 | 508 |

| 267.4 | |||

| 300 | 12 | 325 | 610 |

| 323.9 | |||

| 318 | |||

| 350 | 14 | 377 | 712 |

| 355.6 | |||

| 400 | 16 | 426 | 812 |

| 406.4 | |||

| 450 | 18 | 478 | 914 |

| 457.2 | |||

| 500 | 20 | 529 | 1016 |

| 508 | |||

| 550 | 22 | 559 | 1118 |

| 600 | 24 | 630 | 1220 |

| 610 | |||

| 650 | 26 | 660 | 1320 |

| 700 | 28 | 720 | 1422 |

| 711 | |||

| 750 | 30 | 762 | 1524 |

| 800 | 32 | 820 | 1626 |

| 813 | |||

| 850 | 34 | 864 | 1728 |

| 900 | 36 | 920 | 1828 |

| 914 | |||

| 950 | 38 | 956 | 1930 |

| 1000 | 40 | 1016 | 2032 |

| 1020 | |||

| 1050 | 42 | 1067 | 2134 |

| 1100 | 44 | 1118 | 2236 |

| 1120 | |||

| 1150 | 46 | 1168 | 2336 |

| 1200 | 48 | 1220 | 2440 |

| Nominal Diameter | Outer Diameter (mm) | Distance from Center to Center (mm) | |

|---|---|---|---|

| DN | NPS | OD | O |

| 25 | 1 | 32 | 50 |

| 33.4 | |||

| 32 | 1-1/4 | 38 | 64 |

| 42.2 | |||

| 40 | 1-1/2 | 45 | 76 |

| 48.3 | |||

| 50 | 2 | 57 | 102 |

| 60.3 | |||

| 65 | 2-1/2 | 76 | 128 |

| 73 | |||

| 80 | 3 | 89 | 152 |

| 90 | 3-1/2 | 101.6 | 178 |

| 100 | 4 | 108 | 204 |

| 114 | |||

| 125 | 5 | 133 | 254 |

| 141.3 | |||

| 139.7 | |||

| 150 | 6 | 168.3 | 304 |

| 159 | |||

| 165 | |||

| 200 | 8 | 219 | 406 |

| 216 | |||

| 250 | 10 | 273 | 508 |

| 267.4 | |||

| 300 | 12 | 325 | 610 |

| 323.9 | |||

| 318 | |||

| 350 | 14 | 377 | 712 |

| 355.6 | |||

| 400 | 16 | 426 | 812 |

| 406.4 | |||

| 450 | 18 | 478 | 914 |

| 457.2 | |||

| 500 | 20 | 529 | 1016 |

| 508 | |||

| 550 | 22 | 559 | 1118 |

| 600 | 24 | 630 | 1220 |

| 610 | |||

| 650 | 26 | 660 | 1320 |

| 700 | 28 | 720 | 1422 |

| 711 | |||

| 750 | 30 | 762 | 1524 |

| 800 | 32 | 820 | 1626 |

| 813 | |||

| 850 | 34 | 864 | 1728 |

| 900 | 36 | 920 | 1828 |

| 914 | |||

| 950 | 38 | 956 | 1930 |

| 1000 | 40 | 1016 | 2032 |

| 1020 | |||

| 1050 | 42 | 1067 | 2134 |

| 1100 | 44 | 1118 | 2236 |

| 1120 | |||

| 1150 | 46 | 1168 | 2336 |

| 1200 | 48 | 1220 | 2440 |

Butt weld elbows can change the flow direction of fluid in a piping system. It can redirect the flow of fluid from one direction to another, allowing for adjustments in the flow direction within the piping system.

#

Narito ang katalogo ng produkto at data sheet para sa iyong reference. Higit pang impormasyon ay makipag-ugnay sa amin.