Ogni giorno

- Casa

- Perché Snowate

- Ricambi

-

Pompa ad alta pressione di desalinizzazione

-

Pompa CNP

-

Modulo EDI

-

Membrane

-

Resine di scambio ionico

-

Prodotti chimici per il trattamento delle acque

-

Alloggiamento filtro di precisione/sicurezza

-

Alloggiamento del filtro autopulente

-

Alloggiamento filtro alimentare e farmaceutico

-

Cartucce filtranti

-

Sacchetti filtro

-

Valvole termoplastiche

-

Valvola di metallo

-

Strumento Supmea

-

Strumento CREATEC

-

Manometro

-

Valvola solenoide

-

Misuratore di portata

-

Pompa di dosaggio SEKO

-

Snowate Pompa di misurazione

-

Valvole e raccordi in plastica

-

Sterilizzatore UV dell'acqua

-

Generatore di ozono

-

Generatore di ozono industriale

-

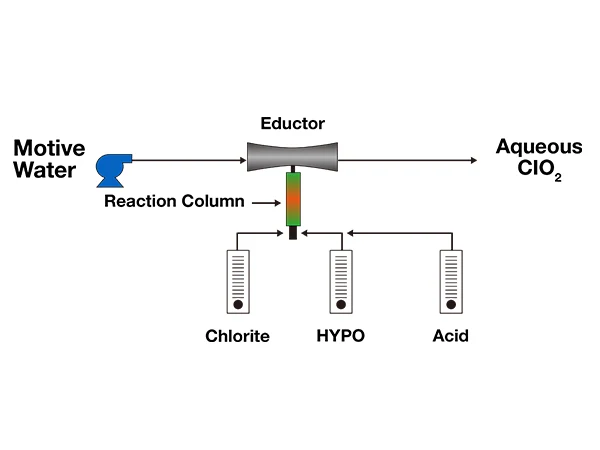

Chlorinated Disinfection Equipment

-

Valvole di controllo multiporta

-

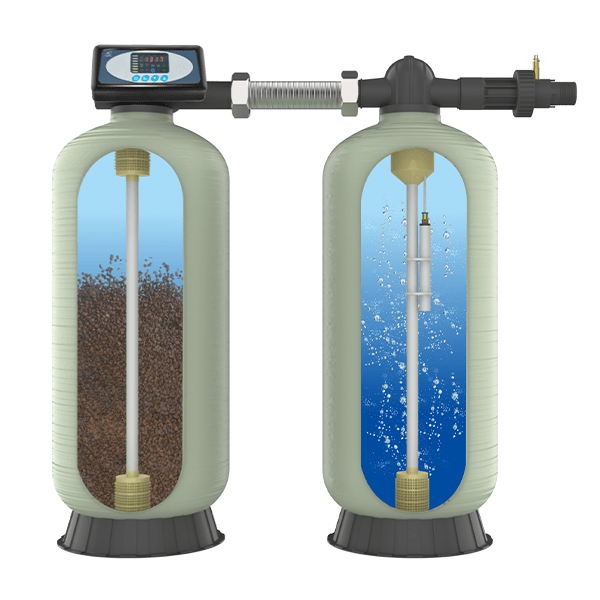

Serbatoi FRP

-

Alloggiamenti a membrana

-

Raccordi per saldatura a testa alta

-

Accessori per tubi

-

Regolatore di pressione della pompa

-

Controllo dell'automazione

-

Trattamento delle acque reflue

-

- Sistemi

- Industria

- Soluzioni

- Conoscenza e calcolatrice

- Risorse

- Contatto