Explanation of membrane product knowledge

To further enhance the sales staff's understanding of membrane products and deepen technical communication, the company recently organized a visit to a membrane production workshop for the sales team. This comprehensive visit covered both theoretical and practical aspects, providing participants with a thorough understanding of membrane product knowledge and the sophisticated manufacturing processes involved.

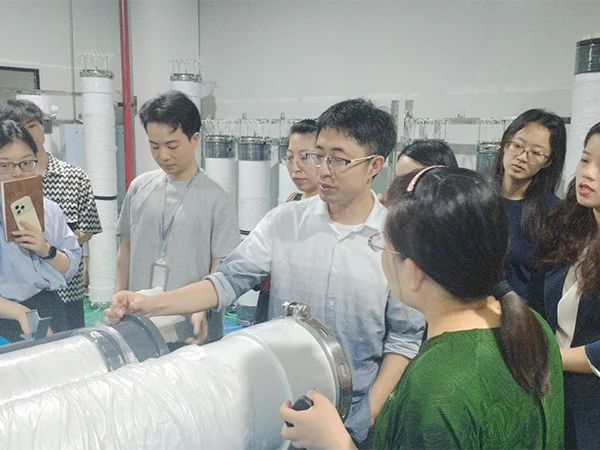

Explanation of membrane product knowledge

Explanation of the UF membrane production process

UF membrane water immersion test

At the start of the visit, a technical department engineer provided the sales team with a detailed explanation of membrane product classifications, application scenarios, and key advantages. From UF membranes and MBR membrane modules to membrane filament materials, comprehensive answers were provided to address the issues encountered by sales personnel during practical application. The training content was practical and relevant, enabling sales personnel to gain a more comprehensive understanding of product performance and advantages.

Explanation of the MBR membrane production process

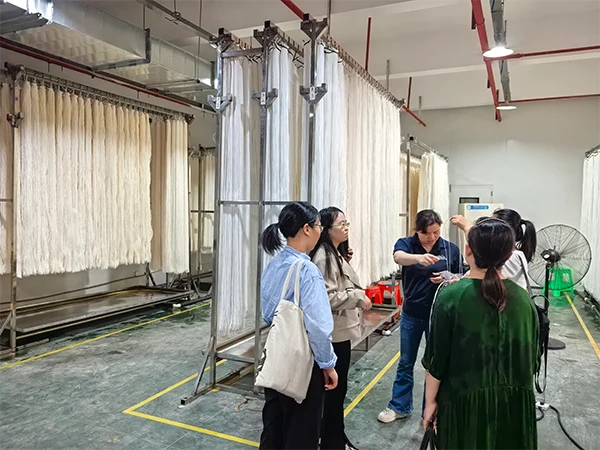

Membrane fiber production

Dinner together

Subsequently, the workshop director led the sales team on a tour of the membrane production workshop. In the UF membrane production area, the sales staff gained an in-depth understanding of key processes, including membrane sheet forming, encapsulation, and inspection. The staff provided a detailed introduction to the operating mechanisms of the automated equipment and the product quality control system, giving the team a direct and in-depth understanding of membrane production. Entering the MBR membrane module production line, the clean, orderly workshop environment and the efficient, intelligent production processes were particularly impressive. From membrane fiber weaving and module assembly to the final inspection of complete modules, each process is executed with rigor and meticulous attention to detail, ensuring product stability and reliability.

During a relaxed and enjoyable dinner, staff and the sales team discussed and shared industry trends, and explored future developments. This visit was not only an enriching learning experience but also fostered intellectual and emotional connections.

This visit and exchange activity provided the sales team with a firsthand understanding of the membrane production process and further strengthened their confidence in providing excellent customer service. Moving forward, we will continue to organize various on-site visits and technical exchange activities to promote the high-quality development of membrane purification technology.