Specification

Table 1: Oxygen Source Industrial Ozone Generator Technical Parameters

| Type |

Ozone Production |

Oxygen |

Ozone Concentration |

Cooling water flow |

Power |

Ozone Room Dimensions |

Pipeline |

PSU Dimensions |

Type |

| kg/h |

Nm3/h |

mg/l |

m3/h |

KW/h |

mm |

Cooling water |

Gas Pipeline |

| SOGO-500G |

0.5 |

4 |

120–148 |

1 |

5 |

1000 × 1000 × 1985 |

DN20 |

DN15 |

700 × 1000 × 2100 |

| SOGO-800G |

0.8 |

6.4 |

120–148 |

1.6 |

7.5 |

1000 × 1000 × 1985 |

DN20 |

DN15 |

700 × 1000 × 2100 |

| SOGO-1KG |

1 |

8 |

120–148 |

2 |

≤ 7.5 |

1000 × 1000 × 1985 |

DN25 |

DN15 |

700 × 1000 × 2100 |

| SOGO-2KG |

2 |

16 |

120–148 |

4 |

≤ 15 |

1000 × 1000 × 1985 |

DN25 |

DN25 |

700 × 1000 × 2100 |

| SOGO-3KG |

3 |

24 |

120–148 |

6 |

≤ 22.5 |

1000 × 1000 × 1985 |

DN32 |

DN25 |

700 × 1000 × 2100 |

| SOGO-4KG |

4 |

32 |

120–148 |

8 |

≤ 30 |

1100 × 1100 × 1985 |

DN40 |

DN25 |

700 × 1000 × 2100 |

| SOGO-5KG |

5 |

40 |

120–148 |

10 |

≤ 37.5 |

1100 × 1100 × 1985 |

DN40 |

DN25 |

1600 × 1200 × 2200 |

| SOGO-8KG |

8 |

64 |

120–148 |

16 |

≤ 60 |

1400 × 1400 × 2000 |

DN50 |

DN32 |

1600 × 1200 × 2200 |

| SOGO-10KG |

10 |

80 |

120–148 |

20 |

≤ 75 |

1400 × 1400 × 2050 |

DN50 |

DN40 |

1600 × 1200 × 2200 |

| SOGO-15KG |

15 |

120 |

120–148 |

30 |

≤ 112.5 |

1400 × 1400 × 2100 |

DN65 |

DN50 |

1600 × 1200 × 2200 |

| SOGO-20KG |

20 |

160 |

120–148 |

40 |

≤ 150 |

3600 × 1100 × 1800 |

DN80 |

DN50 |

1800 × 1200 × 2200 |

| SOGO-25KG |

25 |

200 |

120–148 |

50 |

≤ 187.5 |

3600 × 1170 × 1845 |

DN80 |

DN65 |

1800 × 1200 × 2200 |

| SOGO-30KG |

30 |

240 |

120–148 |

60 |

≤ 225 |

3600 × 1225 × 1908 |

DN100 |

DN65 |

1800 × 1200 × 2200 |

| SOGO-40KG |

40 |

320 |

120–148 |

80 |

≤ 300 |

3600 × 1375 × 2050 |

DN100 |

DN80 |

2400 × 1500 × 2200 |

| SOGO-50KG |

50 |

400 |

120–148 |

100 |

≤ 375 |

3600 × 1445 × 2120 |

DN100 |

DN80 |

2400 × 1500 × 2200 |

| SOGO-60KG |

60 |

480 |

120–148 |

120 |

≤ 450 |

3600 × 1531 × 2326 |

DN125 |

DN100 |

2700 × 1500 × 2200 |

| SOGO-80KG |

80 |

640 |

120–148 |

160 |

≤ 600 |

3600 × 1728 × 2711 |

DN150 |

DN100 |

3600 × 1500 × 2200 |

| SOGO-100KG |

100 |

800 |

120–148 |

200 |

≤ 750 |

3600 × 1860 × 2850 |

DN200 |

DN125 |

4500 × 1500 × 2200 |

| SOGO-120KG |

120 |

960 |

120–148 |

240 |

≤ 900 |

3600 × 2100 × 2920 |

DN200 |

DN150 |

4500 × 1500 × 2200 |

| SOGO-150KG |

150 |

1200 |

120–148 |

300 |

≤ 1125 |

3600 × 2140 × 3150 |

DN200 |

DN150 |

5400 × 1500 × 2200 |

Ozone Preparation Principle

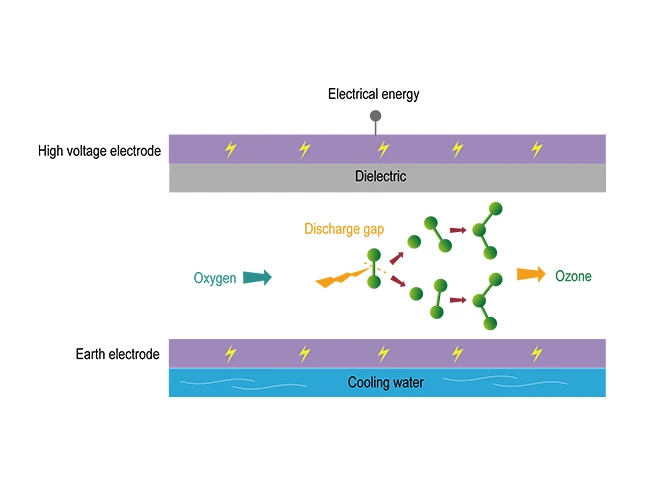

The oxygen source industrial ozone generator uses DBD discharge method to produce ozone, which typically consists of two electrodes: a high-voltage electrode and a ground electrode, with an insulating medium (usually glass) sandwiched between the electrodes.

Pure oxygen flows into the generator from the inlet, and under the application of alternating high voltage, the oxygen gas between the high-voltage electrode and the ground electrode experiences corona discharge. As the voltage increases, the electric field strength rises, exciting and ionizing the oxygen molecules in the gas, releasing free electrons. These free electrons collide with other oxygen molecules (O₂), leading to further ionization and the generation of reactive oxygen atoms (O). These reactive oxygen atoms then combine with oxygen molecules to form ozone (O₃), which is ultimately discharged through the generator's outlet.