Sodium Hypochlorite Generator Product Training

To enhance the company's technical capabilities and service quality in the water treatment industry, we recently organized a training activity focusing on the production workshops for ozone generators and sodium hypochlorite generators. This activity aims to improve the sales team's understanding of these devices and enhance their practical application skills by providing a comprehensive overview of the product production process, structure, and workflow.

Sodium Hypochlorite Generator Product Training

Ozone Generator Product Training

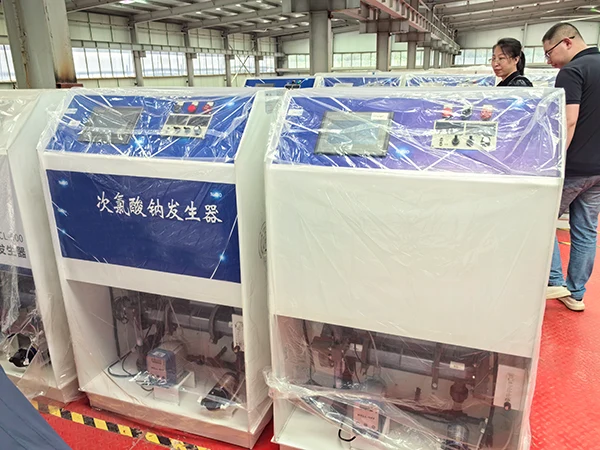

Display of Finished sodium Hypochlorite Generator

During the sodium hypochlorite generator training session, technical engineers focused on the electrolytic preparation principles of sodium hypochlorite generators, emphasizing raw material configuration, electrode selection, electrolysis control, and safe dosing. They also used typical application cases, such as municipal water supply and sewage treatment, to help team members deepen their understanding. Subsequently, the team entered the production workshop to gain a practical understanding of the complete manufacturing process, from electrolytic cell assembly and complete machine wiring to shell anti-corrosion and control system debugging. They also focused on observing the electrode corrosion resistance process and safety control settings. Finally, the team visited the packaging process to learn about the equipment's shockproof, moisture-proof, and other protective measures, ensuring safe and reliable product transportation.

Sodium Hypochlorite Generator Production Process Visit

Sodium Hypochlorite Generator Internal Structure Display

Sodium Hypochlorite Generator Packaging

During the product training for ozone generators, the technical director began by discussing ozone's oxidation disinfection, deodorization, and decolorization properties. They then provided a detailed explanation of core technologies such as the discharge structure, cooling method, and concentration control, using practical scenarios like hospital wastewater treatment and food processing as examples. Afterward, the team toured the workshop's welding assembly and power supply testing areas. They focused on understanding the structure and performance of key components, including the electrode tube, power board, and cooling module. They also observed an equipment operation simulation to learn the operational logic of concentration adjustment and the safety interlock system. Finally, we toured the complete machine testing and packaging process, learning about the shockproof, moisture-proof, and pressure-resistant packaging measures and directly comparing different equipment prototype models.

Explanation of the Control Cabinet Interior

Product Detail Explanation

Ozone Generator Packaging Display

Through this focused study of sodium hypochlorite generators and ozone generators, team members have not only enhanced their systematic understanding of equipment working principles, production processes, and application scenarios, but have also established a strong foundation for future technical exchanges with customers and project promotion. Going forward, the company will continue to organize similar learning activities to continuously enhance the team's professional capabilities and provide customers with more accurate and reliable water treatment solutions.