MBR (Membrane Bio-Reactor) wastewater treatment is a commonly used modern wastewater treatment method. It employs membrane bioreactor technology, which is a new technology combining biological treatment technology and membrane separation technology. It replaces the secondary sedimentation tank in traditional processes and can efficiently perform solid-liquid separation, resulting in stable reclaimed water that can be directly used. The MBR process achieves a removal rate of over 99% for SS (Suspended Solids), over 90% for turbidity, 94% for COD (Chemical Oxygen Demand), 96% for BOD (Biochemical Oxygen Demand), and 97% for ammonia nitrogen.

Content

What is Biological Treatment Technology?

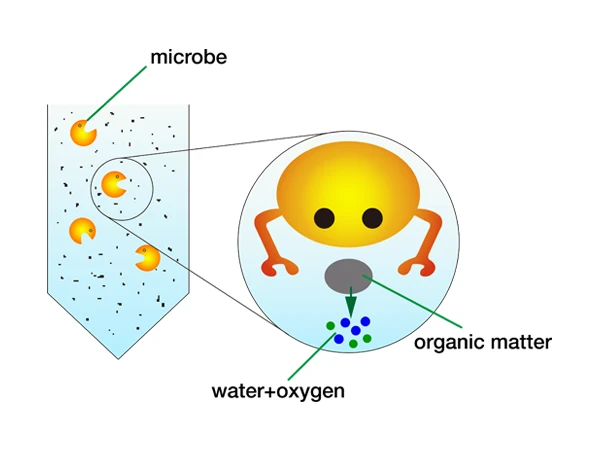

Biological treatment technology is a wastewater treatment method that utilizes microorganisms to oxidize and decompose organic matter and certain inorganic toxins (such as cyanides and sulfides) in wastewater, converting them into stable and harmless inorganic substances.

What is Membrane Separation Technology?

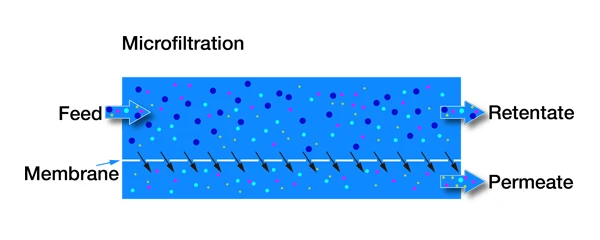

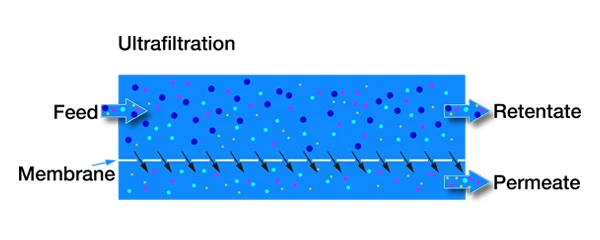

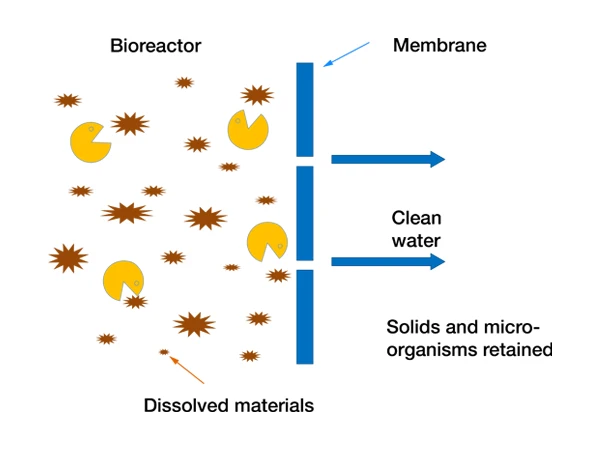

Membrane separation uses membrane materials as the separation medium. When a driving force (such as pressure difference, concentration difference, or potential difference) is generated on both sides of the membrane, components selectively permeate through the membrane to achieve separation. The membranes used in the MBR process are generally microfiltration (MF) membranes and ultrafiltration (UF) membranes.

Microfiltration (MF) Membrane and Ultrafiltration (UF) Membrane

- The pore size of microfiltration membranes typically falls within 0.1–10 μm, with a molecular weight cut-off range of 1,000–500,000 Daltons. They can effectively remove suspended solids, most bacteria, and some viruses from water. Microfiltration is a pressure-driven membrane separation process. Under the pressure difference between the upstream and downstream of the filtration, particles larger than the membrane pore size in the water are retained or adsorbed by the microfiltration membrane, resulting in a purer fluid downstream and achieving solid-liquid separation.

- The pore size of ultrafiltration membranes is between that of nanofiltration membranes and microfiltration membranes. The separation pore size of ultrafiltration membranes falls within 0.001–0.1 μm, with a molecular weight cut-off range of 500–200,000 Daltons, capable of retaining large molecules, bacteria, viruses, etc. Ultrafiltration mainly operates on a sieving mechanism, where under certain pressures (0.1–0.6 MPa), solvents and solutes smaller than the membrane pore size can pass through the membrane, while solutes larger than the membrane pore size cannot, thereby achieving purification, separation, and concentration of the solution.

Introduction to Membrane Bioreactors?

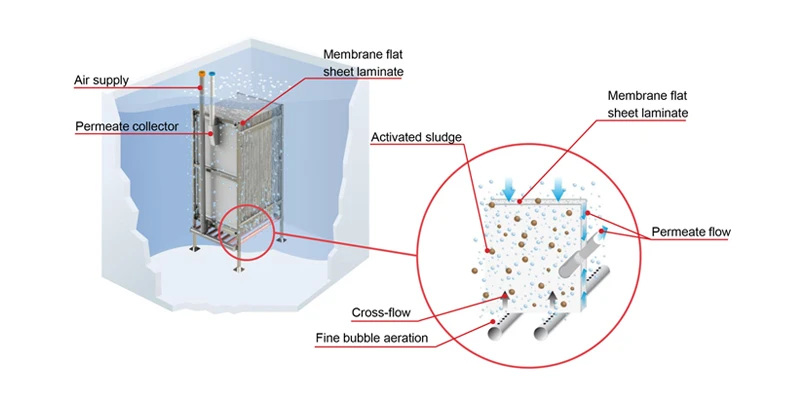

The membrane bioreactor replaces the traditional secondary sedimentation tank at the end of biological treatment technology with a membrane module. It maintains a high concentration of activated sludge in the bioreactor and increases the organic load of biological treatment, thereby reducing the footprint of wastewater treatment facilities and the amount of excess sludge by maintaining a low sludge load. It mainly utilizes membrane separation equipment to retain activated sludge and macromolecular organic matter in the water.

Classification of Membrane Bioreactors

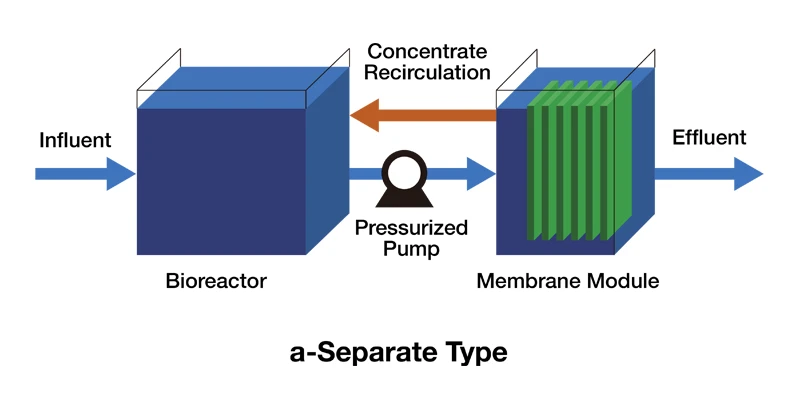

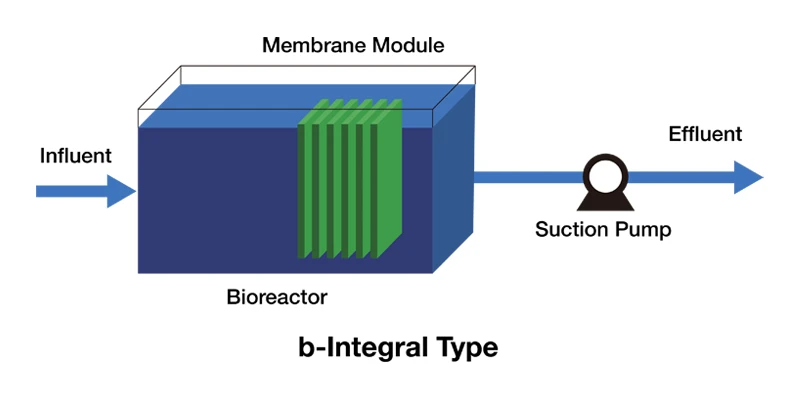

According to the combination method of the membrane module and the bioreactor, MBR can be divided into two types: separate and integrated. In a separate MBR, the membrane separation device operates independently outside the bioreactor, making it easy to control and clean. The integrated MBR immerses the membrane module in the bioreactor. It operates under a low membrane pressure difference through the suction action of a vacuum pump.

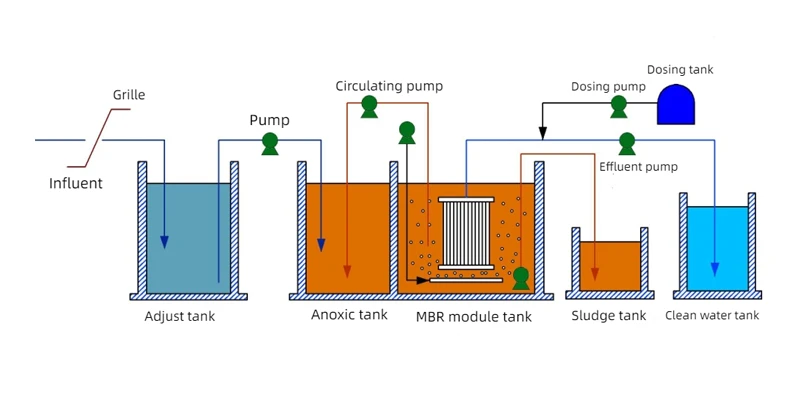

MBR Process Flow?

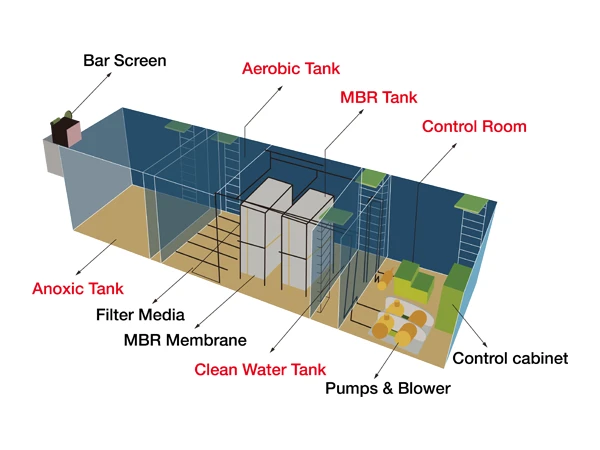

After the wastewater passes through the grid and enters the regulation tank, it is pumped into the bioreactor by the lift pump. The aerator is activated by the PLC controller to oxygenate the bioreactor. The effluent from the bioreactor is pumped into the membrane separation treatment unit by the circulation pump. The concentrated water returns to the regulation tank, and the water from the membrane separation is chlorinated and disinfected before entering the storage tank. This is a typical MBR process flow. You can adjust the structures according to the properties of the water quality.

MBR Process Equipment and Their Functions

The MBR process mainly includes the following 5 units: regulation tank, anoxic tank, MBR tank, equipment room, and clear water tank. Its internal components include bioreactors, membrane modules, tanks, blower aeration systems, lift pumps, pipelines, valves, instruments, etc.

- Regulation tank. The regulation tank mainly adjusts the quantity and quality of wastewater, and can also serve as a storage place for emergency drainage.

- Anoxic tank. It provides a place for denitrification of wastewater, while large organic molecules are decomposed into small molecules under the action of hydrolytic enzymes, improving the biodegradability of the wastewater.

- MBR tank. The Membrane Bioreactor (MBR) is a place where microorganisms degrade organic matter.

- Clear water tank. The clear water tank serves as a storage tank and is also used as a dosing tank for membrane cleaning. Additionally, it functions as a high-level water tank to prevent siphoning when the suction pump stops operating.

- Equipment room. The equipment room is a place for placing electromechanical equipment.

Factors Affecting MBR Process Performance

- Temperature

The membrane bioreactor system should operate at 15 °C – 35 °C. As the temperature increases, it reduces the viscosity of the activated sludge mixed liquor, thereby reducing the permeation resistance and increasing the membrane flux.

- Operating Pressure

Under the condition that the properties of the activated sludge mixed liquor remain basically unchanged, the membrane flux increases with the increase in pressure; However, when the pressure reaches a certain value, i.e., when concentration polarization causes the solute concentration on the membrane surface to reach the limit concentration, further increasing the pressure can hardly improve the membrane flux and instead exacerbates membrane fouling. The transmembrane pressure difference of submerged MBR should not exceed 0.05 MPa.

- Dissolved Oxygen

Dissolved oxygen is an important factor affecting the removal efficiency of organic matter. Especially in cases where nitrogen and phosphorus removal is the goal, controlling the concentration of dissolved oxygen becomes even more crucial. In different types of membrane bioreactor processes, mixed liquor forms aerobic, anoxic, and anaerobic zones in the bioreactor in various ways. The control range of DO in each section of the reaction tank is as follows: the anaerobic section is below 0.2 mg/L, the anoxic section is between 0.2 mg/L and 0.5 mg/L, and the dissolved oxygen concentration in the aerobic section should not be less than 2 mg/L.

- Membrane Surface Velocity

The influence of membrane surface velocity and pressure on membrane flux is interrelated. When the pressure is low, the membrane surface velocity has little effect on the membrane flux, but when the pressure is high, the membrane surface velocity has a significant impact on the membrane flux. On one hand, the increase in membrane surface velocity enhances the shear force of the water flow, reducing the deposition of pollutants on the membrane surface; On the other hand, increasing the velocity can enhance the convective mass transfer coefficient, reduce the thickness of the boundary layer, and mitigate the effects of concentration polarization.

- MLSS (Mixed Liquor Suspended Solids Concentration)

The sludge concentration in the aerobic zone of a submerged MBR should be controlled within 3,000 mg/L – 20,000 mg/L. Generally speaking, at a certain membrane surface velocity, when the sludge concentration in the feed liquid increases, the high sludge concentration can easily cause sludge to deposit on the membrane surface, forming a thick sludge layer, which increases filtration resistance and decreases membrane flux. However, the sludge concentration in the feed liquid should not be too low, otherwise the degradation rate of pollutants will be low, and the adsorption and degradation capacity of activated sludge for dissolved organic matter will weaken, resulting in an increase in the concentration of dissolved organic matter in the supernatant of the mixed liquor. This can easily lead to adsorption on the membrane surface, increasing filtration resistance and decreasing membrane flux. Therefore, it is necessary to maintain an appropriate sludge concentration in the feed liquid, as too high or too low will reduce the water flux.

- pH Value

The influent pH value of the membrane bioreactor should be 6–9.

Advantages of MBR Process

- The membrane module can separate macromolecular compounds and microorganisms, resulting in good effluent quality that can be directly reused;

- The pretreatment process is simple, does not require a large amount of chemical additives, and the operation process is straightforward;

- MBR has a high volumetric load and strong impact resistance;

- MBR can directly separate sludge and water, omitting the secondary sedimentation tank step, which reduces the footprint and saves costs;

- The MBR process has strong modular characteristics, is easy to operate, and is easy to automate.

Disadvantages of the MBR Process

- High investment. The cost of membrane modules is high, resulting in an investment increase of approximately 30%–50% compared to conventional treatment methods.

- High energy consumption. Firstly, the MBR sludge-water separation process must maintain a certain membrane driving pressure. Secondly, the MLSS concentration in the MBR tank is very high, requiring increased aeration intensity to maintain sufficient oxygen transfer rates. Additionally, to increase membrane flux and reduce membrane fouling, the flow rate must be increased to scour the membrane surface. Therefore, the energy consumption of MBR is higher than that of traditional biological treatment processes.

- Membranes are prone to fouling and require regular cleaning. This brings inconvenience to operation management and also consumes some chemicals.

- Limited by membrane material. Due to material technology reasons, the current lifespan of membranes is relatively short. The general lifespan of membrane modules is about 5 years, after which they need to be replaced, increasing costs.