Working Principle

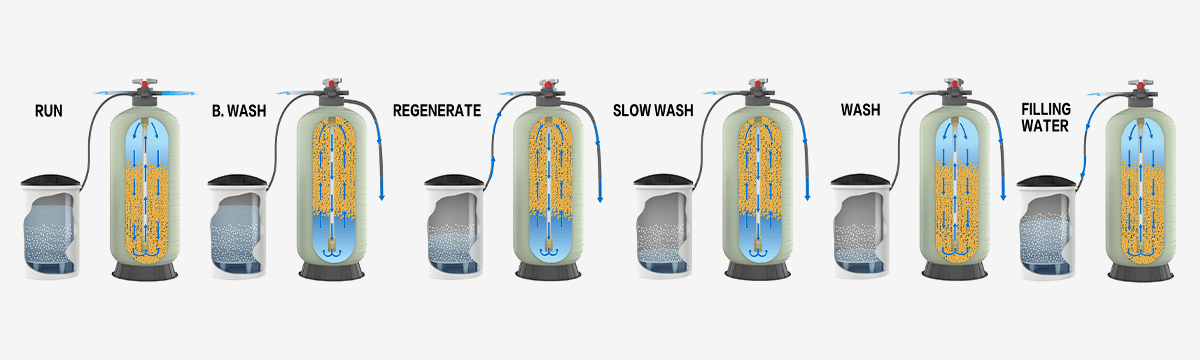

Stage 1: RUN (Softening)

Switch the button to the "RUN" position and the system starts to soften. Raw water enters the control valve from the water inlet and enters the FRP tank and resin layer through the top water distributor, softened water flows along the center pipe and drains from the outlet. The softening process is complete.

Stage 2: Backwash

When the softening performance cannot meet the requirements, the backwash station starts. Switch the button to the "Backwash" position. Raw water enters the control valve from the water inlet and enters the FRP tanks along the inlet pipe and downstream water distributor to eliminate resin impurities. Then the water is discharged from the discharge port.

Stage 3: Regenerate

When the backwash is completed, the generation station starts. Switch the button to the "Generate" position, and raw water enters the control valve from the water inlet and enters the brine ejector. Water flows rapidly to the ejector outlet and produces negative pressure. The brine is drawn into the tanks and flows through the resin layer along the central pipe and the bottom water distributor to achieve resin regeneration. Rare water is then discharged from the discharge port.

Stage 4: Slow Wash

Switch the button to the "Slow Wash" station. The brine ball valve is closed, raw water enters the control valve from the inlet and then enters the tanks through the ejector, and continues to slowly wash the resin layer along the central pipe and bottom water distributor to eliminate resin impurities and brine. Then the water is discharged from the discharge port.

Stage 5: Wash

Raw water enters the control valve from the inlet and then enters the tanks through the top water distributor and flows towards the resin layer with a large amount of water to thoroughly flush the resin layer and residual brine, then the impurities and residual brine will be discharged from the discharge port.

Stage 6: Filling Water

Switch the button to the "Filling Water" station. Raw water enters the control valve through the inlet and the brine ball valve opens at the same time. The water enters the brine tank and fills the water. Upon completion of filling, it will enter the "RUN" (softening) station again.