What is water hardness?

The AO Process (Anaerobic-Oxic Process) is mainly used for wastewater treatment and can effectively remove various pollutants, including organic matters and nitrogen. The treatment efficiency of this process generally reaches: 70%–90% forBOD5, 60%–90% for COD, and over 70% for total nitrogen.

Content

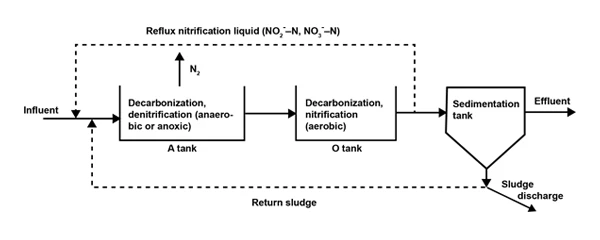

Basic Principles of AO Process

In the A stage of the AO process, heterotrophic bacteria hydrolyze suspended pollutants such as starch, fiber, and carbohydrates, as well as soluble organic matter in the wastewater, into organic acids. This process breaks down macromolecular organic matter into small molecular organic matter, and converts insoluble organic matters into soluble organic matter. When these hydrolyzed products enter the aerobic tank for aerobic treatment, it can improve the biodegradability and oxygen efficiency of the wastewater; In the A stage, heterotrophic bacteria ammonify pollutants such as proteins and fats, releasing ammonia. In the O stage, autotrophic bacteria oxidize NH3-N (NH4+) to NO3- through nitrification. The NO3- is then returned to the A tank via recirculation, where it is reduced to molecular nitrogen (N2), completing the cycle of C, N, and O in the ecosystem and achieving harmless wastewater treatment.

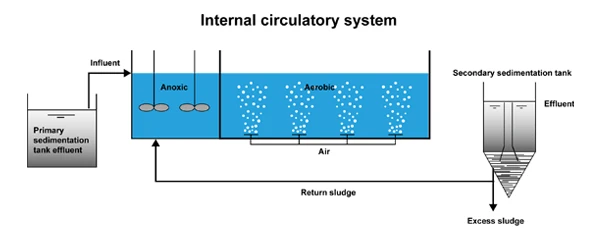

AO Process Flow

After sewage is collected by the drainage system, it enters the bar screen pit of the sewage treatment plant. After removing particulate debris, it is pumped by the lift pump to the primary sedimentation tank for sedimentation. The wastewater then flows by gravity to the A-level biological contact oxidation tank, where it undergoes acidification, hydrolysis, and nitrification-denitrification to reduce organic matter concentration and remove some ammonia nitrogen. It then flows into the O-level biological contact oxidation tank for aerobic biochemical reactions, where most of the organic pollutants are degraded through biological oxidation and adsorption. The effluent then flows by gravity to the secondary sedimentation tank for solid-liquid separation. The supernatant from the sedimentation tank flows into the disinfection tank, where chlorine tablets are added to dissolve and kill harmful bacteria in the water, meeting the discharge standards.

Debris intercepted by the bar screen is regularly loaded into carts and dumped at the landfill. Part of the sludge from the secondary sedimentation tank is returned to the A-level biological treatment tank, while the remaining sludge is sent to the sludge pit for digestion and then periodically extracted and transported for disposal. The supernatant from the sludge pit is returned to the primary sedimentation tank for further treatment.

For calculations related to return sludge and return digestion liquid, refer to AAO Process.

AO Water Treatment Structures and Functions

The overall AO process includes four parts: primary pretreatment, secondary biological treatment, tertiary advanced treatment, and sludge treatment. The specific structures and their functions are as follows:

- Primary Pretreatment

- Primary Sedimentation Tank: The primary sedimentation tank performs solid-liquid separation to remove larger solid suspended particles from the wastewater, reducing the organic load on biological treatment and enhancing the activity of microorganisms in the activated sludge.

- Secondary Biological Treatment

- A-Stage Biological Treatment Tank: Large molecular organic matter is hydrolyzed into small molecular organic matter. At the same time, through the action of returning nitrate nitrogen and nitrifying bacteria, partial nitrification and denitrification can occur, removing ammonia nitrogen.

- O-level Biological Treatment Tank: This tank is divided into two sections. The first section removes various organic substances from the wastewater, significantly reducing the organic matter content in the wastewater. In the latter section, ammonia nitrogen in the wastewater is degraded under sufficient oxygen conditions, while the COD value in the wastewater is also reduced to a lower level, thus purifying the wastewater.

- Secondary Sedimentation Tank: It conducts solid-liquid separation to remove the biofilm and suspended sludge that have peeled off from the biochemical tank, thereby truly purifying the wastewater.

- Tertiary Advanced Treatment

- Disinfection Tank: The effluent from the secondary sedimentation tank flows into the disinfection tank for disinfection, ensuring that the effluent quality meets sanitary standards and is discharged in compliance.

- Sludge Treatment

- Sludge Storage Tank: Sludge from the secondary sedimentation tank is periodically discharged into the sludge storage tank for sludge thickening and aerobic digestion.

- Filter Press: The sludge filter press is used to effectively separate water from solids in the sludge, reducing the volume of the sludge.

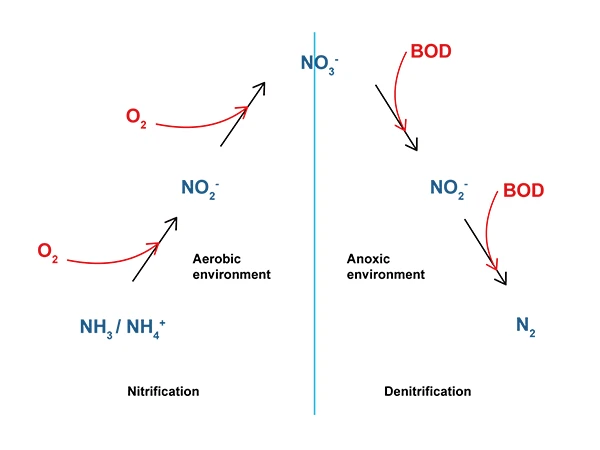

Basic Principle of AO Denitrification

Principle of AO process for biological removal of ammonia nitrogen: Ammonia nitrogen in the wastewater is nitrified to nitrate nitrogen by nitrifying bacteria under oxygenated conditions (O stage). A large amount of nitrate nitrogen is recirculated to the A stage, where under anoxic conditions, it is reduced to harmless nitrogen gas by facultative anaerobic denitrifying bacteria using organic matter in the wastewater as an electron donor and nitrate nitrogen as an electron acceptor.

Control Parameters of AO Process

The operation of wastewater treatment requires the reasonable adjustment of numerous control parameters to ensure the normal and efficient operation of the treatment process. The following are several factors affecting the operation of the AO process:

- pH Value

The pH range that a general wastewater treatment system can withstand is 6–9. A pH value that is too low will result in small coagulated flocs and weakened protozoan activity in biological treatment; A pH value that is too high will result in coarse coagulated flocs, turbid effluent, disintegration of activated sludge, and death of protozoa.

- B/C Ratio

B/C refers to the biodegradability of the system's influent. For activated sludge systems, it is generally considered that B/C ≥ 0.3 indicates good biodegradability. When biodegradability < 0.3, the organic matter content in the wastewater is insufficient to meet the growth needs of microorganisms in biological treatment, and organic nutrients should be added to the wastewater.

- Hydraulic Retention Time (HRT)

HRT refers to the average hydraulic retention time, which is the average time that the wastewater to be treated stays in the reactor. For biological treatment, HRT must meet the corresponding process requirements. Otherwise, if the hydraulic retention time is insufficient, the biochemical reaction will be incomplete, resulting in a lower treatment level; if the hydraulic retention time is too long, it will lead to sludge aging in the system.

- Sludge Concentration MLSS and MLVSS

MLSS is the concentration of activated sludge, and MLVSS is the concentration of volatile activated sludge, generally accounting for 55%–75% of MLSS. The concentration of activated sludge is generally controlled at 2000–4000 mg/L. Excessively high sludge concentration will lead to sludge aging and reduced shock load resistance of the reaction tank; Excessively low sludge concentration will cause the sludge activity to be too strong, which is not conducive to settling, or the reaction nutrients will be insufficient.

- F/M

F/M is called sludge organic load. The F/M range for the AO process is 0.1–0.15. Too low often results in poor sludge activity and reduced pollutant removal rate; If the F/M ratio is too high, the excess carbon source cannot be metabolized into the aeration tank, affecting the nitrification reaction.

- Sludge Retention Time (SRT)

The sludge age in the denitrification process is generally controlled at around 15–20 days. If the sludge age is too short, many microorganisms are discharged from the system before they can reproduce, and the lack of dominant microorganisms with specific functions is not conducive to the degradation of organic pollutants. On the other hand, if the sludge age is too long, the sludge will age, causing sludge to float in the secondary sedimentation tank and resulting in turbid effluent.

- C/N

In the denitrification system, denitrification requires the use of a carbon source for nitrogen removal, while the carbon source has an 'inhibitory' effect on nitrification. Therefore, in the AO denitrification system, the C/N ratio must be within an appropriate range to ensure normal denitrification.

- Reflux Ratio

The reflux ratio of the AO denitrification process includes internal reflux ratio and external reflux ratio. External reflux, also known as sludge reflux, is generally controlled within the range of 30%–70%. Internal reflux, also known as nitrified liquid reflux, involves returning the nitrate nitrogen produced by the nitrification reaction in the aeration tank to the denitrification tank for denitrification reaction. The internal reflux ratio is generally controlled within the range of 200%–400%.

Advantages and Disadvantages of AO Process

Advantages:

- High efficiency, this process has a high removal efficiency for organic matter, ammonia nitrogen, etc., in wastewater.

- Simple process, low investment, and low operating costs. This process uses the organic matter in wastewater as the carbon source for denitrification, thus eliminating the need for additional expensive carbon sources.

- The anoxic denitrification process has a high degradation efficiency for pollutants. For example, the removal rates of COD, BOD5, and nitrogen in the anoxic section are 67%, 40%, and 60%, respectively. The removal rates of phenol and organic matter are 60% and 39%, respectively, making the denitrification reaction an economical and energy-saving degradation process.

- The AO process has a strong resistance to load shocks. When the influent quality fluctuates greatly or the pollutant concentration is high, this process can still maintain normal operation, making the operation and management very simple.

Disadvantages:

- Due to the absence of an independent sludge return system, it is difficult to cultivate sludge with unique functions, resulting in a low degradation rate of refractory substances.

- To improve nitrogen removal efficiency, the internal circulation ratio must be increased, thereby increasing operating costs. Additionally, the internal circulation liquid comes from the aeration tank and contains a certain amount of DO, making it difficult for the A section to maintain an ideal anaerobic state, affecting the denitrification effect, and making it challenging to achieve a nitrogen removal rate of 90%.

- The cultivation and utilization of activated sludge consume a large amount of energy and resources, and at the same time, generate a significant amount of excess sludge that needs to be properly treated.

- The process has relatively poor adaptability to water quality and quantity, and is easily affected by shock loads.

- The aeration and oxygen supply process of the AO process generates a certain amount of noise and odor, which requires appropriate treatment and protection.