The Production Process of Butt Weld Fittings

Manufacture

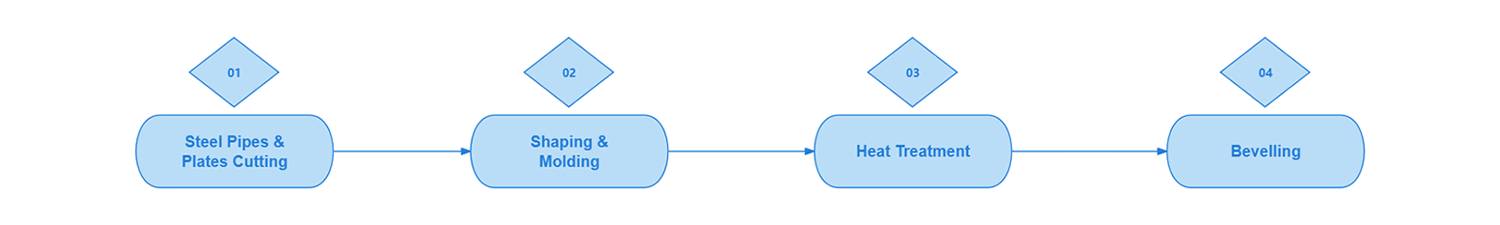

The production process of butt weld fittings is as follows:

Note: Bevelling refers to the groove that the part of weldment to be welded processed and assembled into a certain geometric shape. The bevel is mainly opened for welding the workpiece and ensuring the welding quality. In general, machining method is used to machine the bevelling, however, if the requirements are not high, gas cutting can also be used.

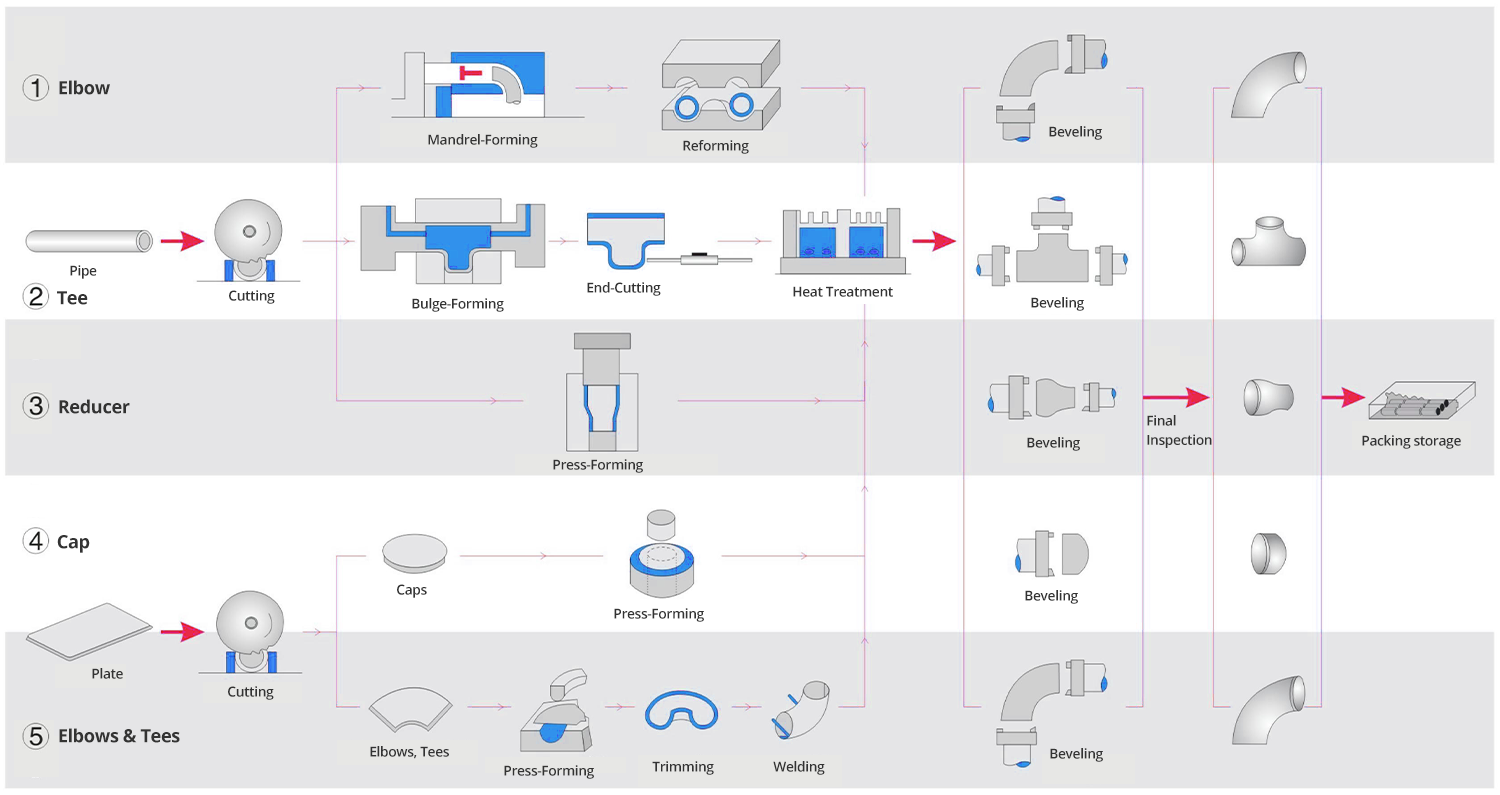

In the production of pipe fittings, steel plates and steel pipes are often used as raw materials to produce elbows, tees, and reducers. Among them, different pipe fittings require different processes in the shaping & molding process. The shaping & molding process of elbows, tees, and reducers produced with steel pipes is as follows:

The elbow is initially shaped using a mandrel, specifically, the mandrel is a metal bar that is used to support the inside of the pipe. It is used to ensure that the pipe maintains a stable shape during the bending process, preventing collapse or deformation of the pipe. After the elbow is made, the mandrel can be removed from the inside of the pipe, leaving the desired internal bending structure, which is then trimmed to obtain the required elbow.

The tee is formed through hydraulic forming. Specifically, the cut steel pipe is placed on a hydraulic machine, and the hydraulic system is controlled to generate thrust, bending the pipe into the desired shape, and then cutting the port to obtain a tee.

The reducer is obtained through stamping. Specifically, the metal material to be processed is placed on a punch press, and the pressure and movement of the upper and lower molds cause the steel pipe to deform and obtain a reducer.

The shaping & molding process of the pipe cap, elbow, and tee produced with steel plates is as follows:

The required model of pipe cap can be manufactured through stamping.

For elbows and tees, after stamping, they also need to go through the process steps of edge trimming and welding forming.

Note: Seamless steel pipes can be processed into seamless pipe fittings, which do not require welding and have no welds. They have better sealing and pressure resistance, and are suitable for high-pressure, high-temperature, or systems with higher sealing requirements. Generally, fittings made from steel plates are welded fittings, which are formed by joining and welding the edges of the steel plates. During the welding process, a weld seam is formed at the joint. This manufacturing process is relatively simple and suitable for general low-pressure piping systems.