D0: Butterfly board to allow freedom of the small set gate flange (in)in diameter (in the butterfly in full on the circumstances) influence over young butterfly plate free gate.

Proper installation and precautions for metal butterfly valves are crucial to ensuring their long-term reliable operation and system safety. Standardized installation not only effectively prevents leakage and maintains system pressure, but also extends valve life, improves operating efficiency, and avoids safety accidents and economic losses caused by valve failures. In addition, correct installation and regular maintenance allow the valve to adapt to various operating conditions, ensuring the continuous and efficient operation of the system, ultimately bringing higher economic benefits and safety guarantees.

Here are the key points and methods for the installation of flanged metal butterfly valves for your reference to ensure the correct installation of the butterfly valve.

Main Points of Installation

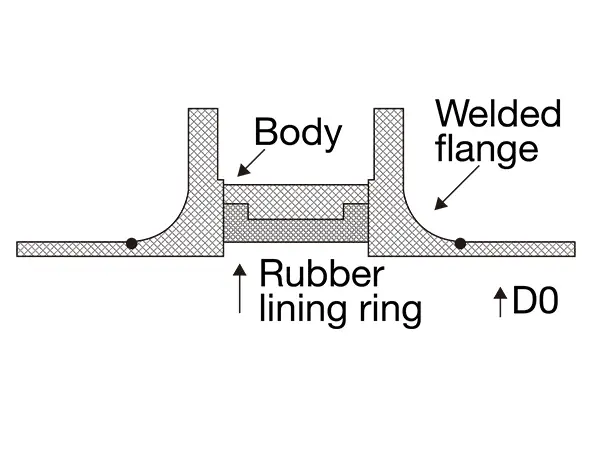

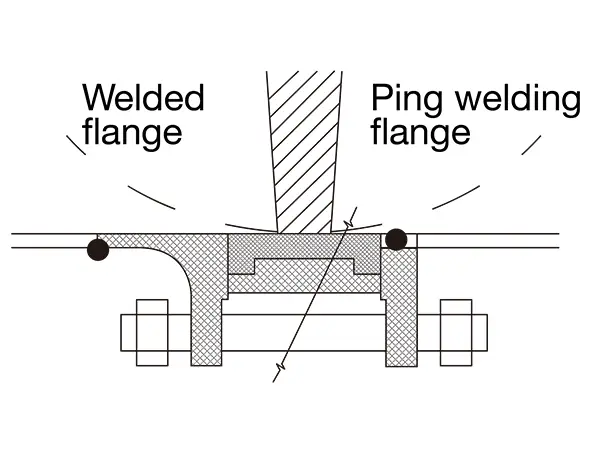

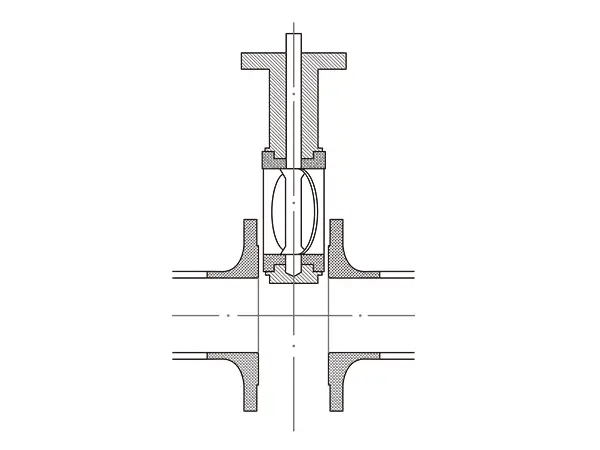

Recommend to use butt welding flange. Do not use flat welding flange because steel pipe can easily meet disc to affect opening.

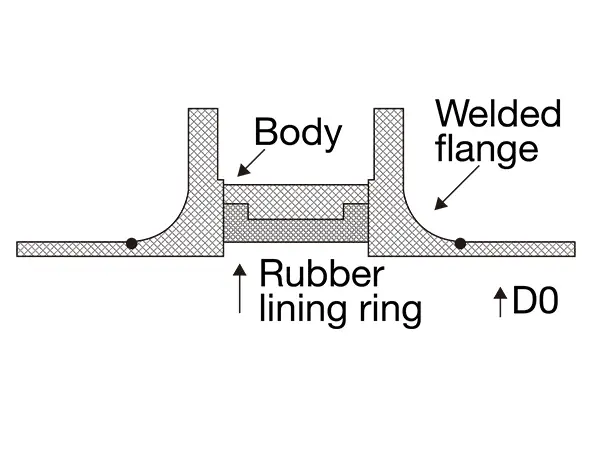

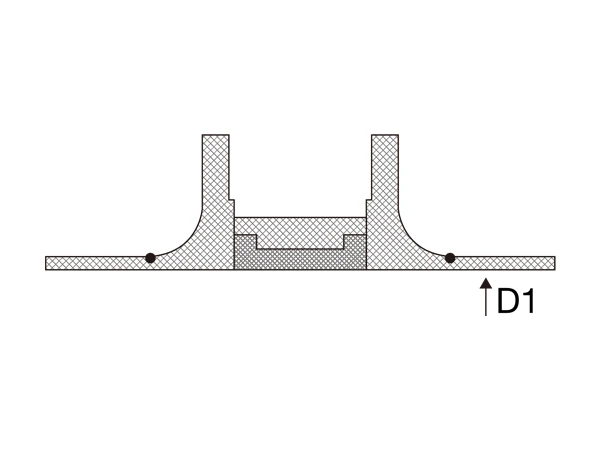

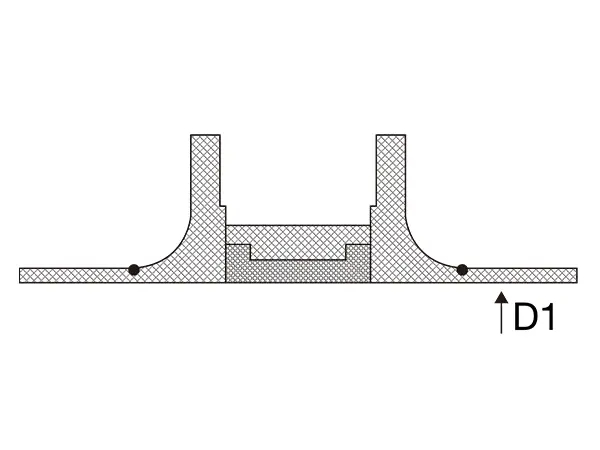

The inner diameter of flange can' t be too small or too big and must confirm the dimension of flange so that the disc can turn free.

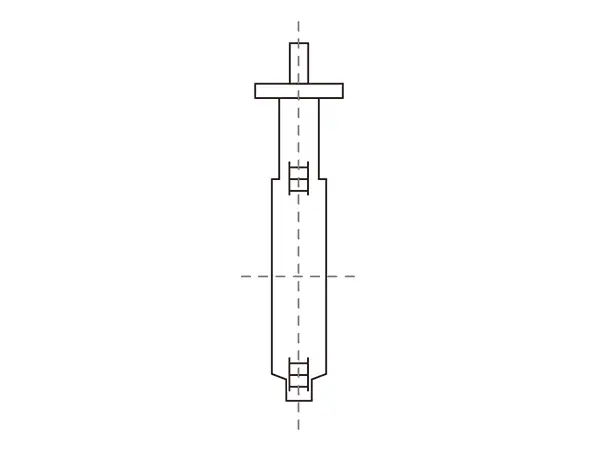

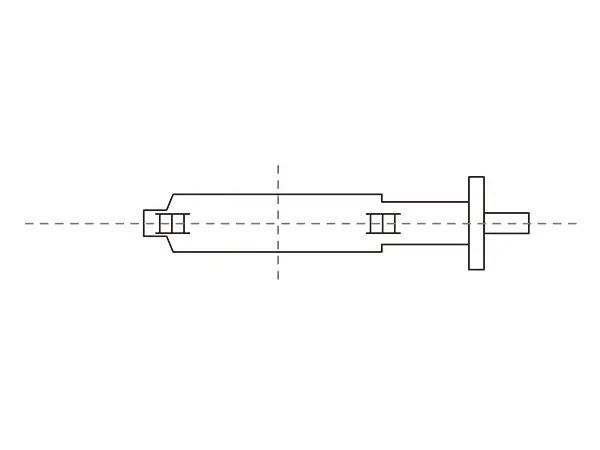

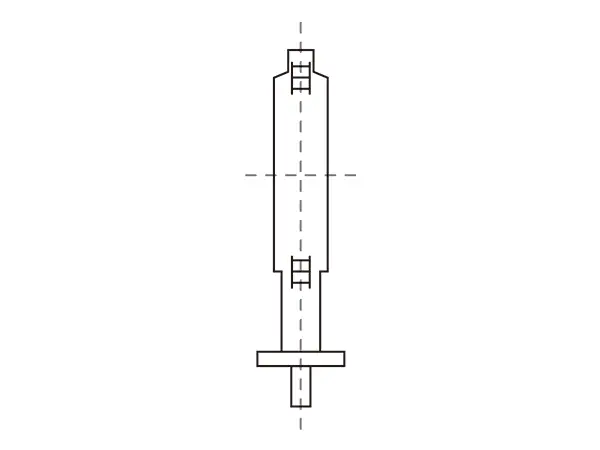

D0: Butterfly board to allow freedom of the small set gate flange (in)in diameter (in the butterfly in full on the circumstances) influence over young butterfly plate free gate.

D1: Best flange (in) diameter

D2: Low flange where the largest (in) diameter flange diameter is too large, will lead to the increased amount of leakage, sealing performance.

Correct Installation

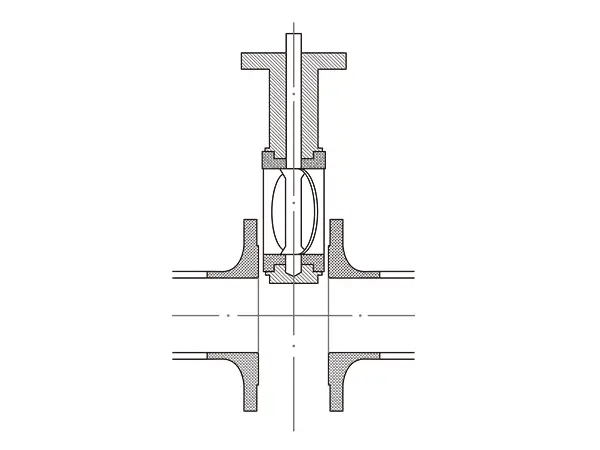

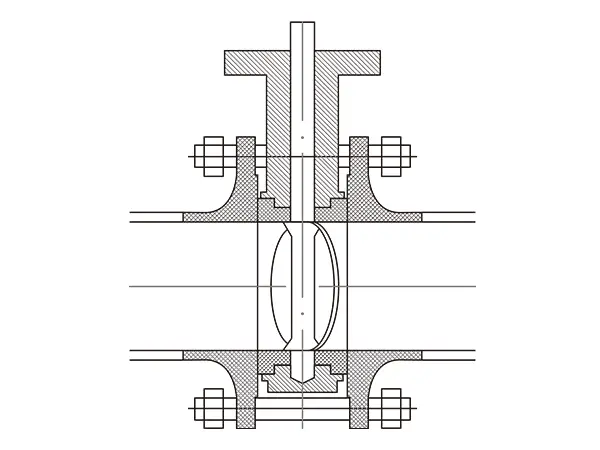

Keeping the biggest space between two flanges so that the whole valve can enter this space (please open valve a little bit) the better way will be that one bolt was hung at the bottom of valve at first. Then turn up and put whole valve into the space between two flanges.

In the disc to be opened in a small angle (not completely closed) state, put all the bolts, but do not tightened.

Fully open the butterfly valves, and confirmed butterfly valve has been in the middle of pipeline, and freedom to operate, and then tightening bolts one by one according to diagonal of flange.

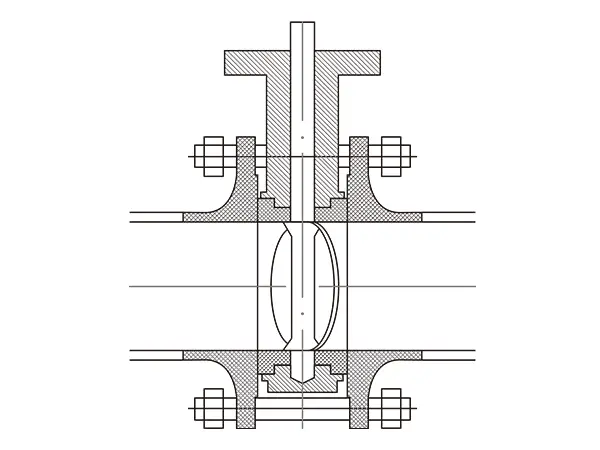

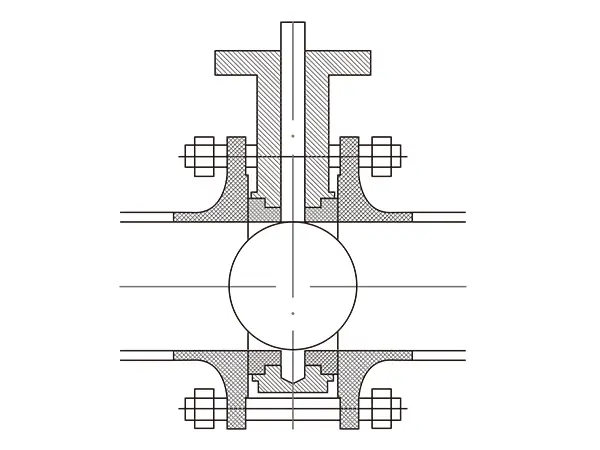

Incorrect Installation

If have not kept the biggest space between two flanges, perhaps the seat can be damaged or rolled up by flanges.

Tightening of the bolt would cause over compressed seat In the butterfly valve to be closed completely state.leading to excessive torque of opening and closing and affecting the normal opening and closing or damaging seat perhaps. Must pay attention to this point!

Do not need to use gaskets for sealing and grease.

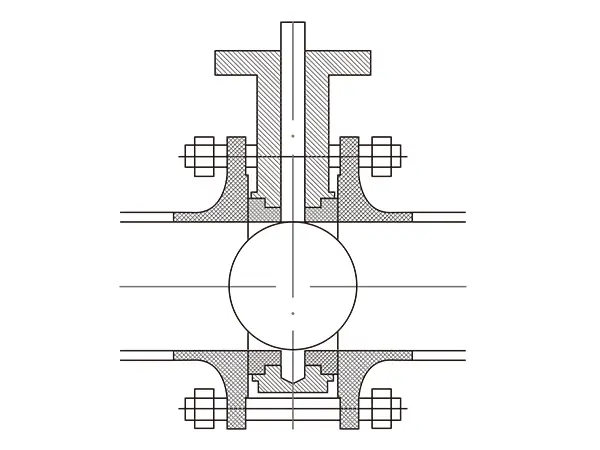

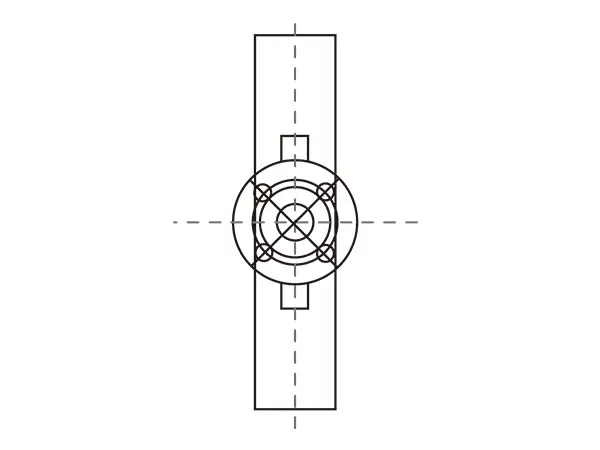

Directions of Installation

The best way is installation horizontally (the stem is in the level state). Impurities is not easy to be deposited at the bottom of valve, and when opening the disc, the valve will have the function of self cleaning. Demand to have same directions between opening the bottom of valve and flow.

Recommended direction: The stem is in level state.

Acceptable direction

Acceptable direction

Un-recommended direction

The above are the installation methods and precautions for flanged butterfly valves. You can use this as a reference for butterfly valve installation. If you encounter any problems that you cannot solve during the installation process, please feel free to contact us, we will do our best to help you.