2-1/2" – 4"

KCV series check valve is a type of valve whose opening and closing part is a circular valve disc that operates based on its own weight and the pressure of the medium to prevent the backflow of the medium. Its main function is to prevent the reverse flow of the medium. When the direction of the medium flow is normal, the valve opens, allowing the fluid to pass through; when the direction of the medium flow reverses, the valve closes, preventing the fluid from flowing back. Check valves are widely used in piping systems to prevent the reverse flow of the medium from affecting the equipment and system.

KCVS-100 Single Union Swing Check Valve

KCVB-100 Double Union Swing Check Valve

KCVB-200 Swing Check Valve Flange Type

KCVC-100 Swing Check Valve Socket Type

KCVC-200 Flanged Swing Check Valve

Feature

Material List

|

S/N | Part | Specification | Qty. |

|---|---|---|---|---|

| 47 | Gasket | EPDM/VITON | 1 | |

| 44 | O-ring | EPDM/VITON | 1 | |

| 42 | O-ring | EPDM/VITON | 1 | |

| 17 | Union end | UPVC/CPVC | 1 | |

| 15 | Nut | UPVC/CPVC | 1 | |

| 08 | Adjust seat | UPVC/CPVC | 1 | |

| 03 | Disc | PVDF | 1 | |

| 01 | Body | UPVC/CPVC | 1 |

| Size | d | d1 | d2 | D | L | L1 | L2 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ANSI | DIN | JIS | CNS | ANSI | DIN | JIS | CNS | ||||||

| 1/2" (15) | 15 | 21.54 | 20.30 | 22.40 | 22.40 | 21.23 | 20.10 | 21.73 | 21.90 | 54.00 | 87.60 | 22.30 | 22.30 |

| 3/4" (20) | 20 | 26.87 | 25.30 | 26.45 | 26.40 | 26.57 | 25.10 | 25.69 | 25.90 | 63.00 | 103.50 | 25.50 | 25.50 |

| 1" (25) | 25 | 33.65 | 32.30 | 32.55 | 34.50 | 33.27 | 32.10 | 31.70 | 33.90 | 73.50 | 120.60 | 28.60 | 28.60 |

| 1-1/4" (32) | 32 | 42.42 | 40.30 | 38.60 | 42.50 | 42.04 | 40.10 | 37.65 | 41.90 | 84.50 | 135.00 | 32.00 | 32.00 |

| 1-1/2" (40) | 40 | 48.56 | 50.30 | 48.70 | 48.60 | 48.11 | 50.10 | 47.74 | 47.90 | 98.00 | 144.00 | 35.00 | 35.00 |

| 2" (50) | 50 | 60.63 | 63.30 | 60.80 | 60.60 | 60.17 | 63.10 | 59.78 | 59.90 | 119.00 | 163.00 | 38.00 | 38.00 |

Feature

Material List

|

S/N | Part | Specification | Qty. |

|---|---|---|---|---|

| 47 | Gasket | EPDM/VITON | 1 | |

| 44 | O-ring | EPDM/VITON | 1 | |

| 42 | O-ring | EPDM/VITON | 1 | |

| 17 | Union end | UPVC/CPVC | 2 | |

| 15 | Nut | UPVC/CPVC | 2 | |

| 08 | Adjust seat | UPVC/CPVC | 1 | |

| 03 | Disc | PVDF | 1 | |

| 01 | Body | UPVC/CPVC | 1 |

| Size | d | d1 | d2 | D | L | L1 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ANSI | DIN | JIS | CNS | ANSI | DIN | JIS | CNS | |||||

| 1/2" (15) | 15 | 21.54 | 20.30 | 22.40 | 22.40 | 21.23 | 20.10 | 21.73 | 21.90 | 54.00 | 93.60 | 22.30 |

| 3/4" (20) | 20 | 26.87 | 25.30 | 26.45 | 26.40 | 26.57 | 25.10 | 25.69 | 25.90 | 63.00 | 110.00 | 25.50 |

| 1" (25) | 25 | 33.65 | 32.30 | 32.55 | 34.50 | 33.27 | 32.10 | 31.70 | 33.90 | 73.50 | 125.60 | 28.60 |

| 1-1/4" (32) | 32 | 42.42 | 40.30 | 38..60 | 42.50 | 42.04 | 40.10 | 37.65 | 41.90 | 84.50 | 142.00 | 32.00 |

| 1-1/2" (40) | 40 | 48.56 | 50.30 | 48.70 | 48.60 | 48.11 | 50.10 | 47.74 | 47.90 | 98.00 | 153.00 | 35.00 |

| 2" (50) | 50 | 60.63 | 63.30 | 60.80 | 60.60 | 60.17 | 63.10 | 59.78 | 59.90 | 119.00 | 173.00 | 38.00 |

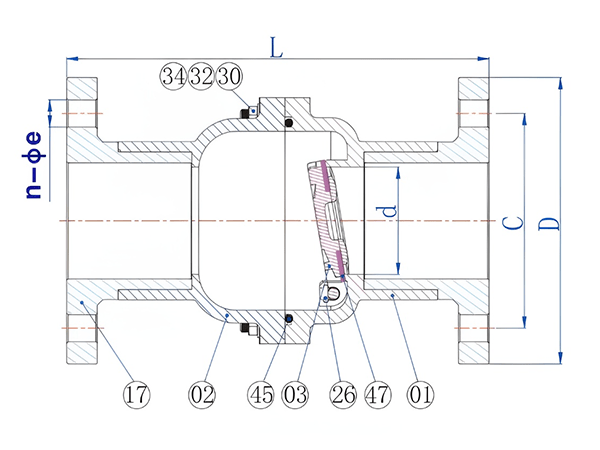

Feature

Material List

|

S/N | Part | Specification | Qty. |

|---|---|---|---|---|

| 47 | Gasket | EPDM/VITON | 1 | |

| 44 | O-ring | EPDM/VITON | 2 | |

| 42 | O-ring | EPDM/VITON | 1 | |

| 26 | Nut | UPVC/CPVC/PPH/PVDF | 2 | |

| 17 | Flange | UPVC/CPVC/PPH/PVDF | 2 | |

| 15 | Buckle | UPVC/CPVC/PPH/PVDF | 2 | |

| 08 | Adjust seat | UPVC/CPVC/PPH/PVDF | 1 | |

| 03 | Disc | PVDF | 1 | |

| 01 | Body | UPVC/CPVC/PPH/PVDF | 1 |

| Size | d | C | D | L | n-φe | ||

|---|---|---|---|---|---|---|---|

| ANSI | JIS | DIN | |||||

| 1/2" (15) | 15 | 60.50 | 70.00 | 65.00 | 95.00 | 126.00 | 4–15 |

| 3/4" (20) | 20 | 70.00 | 75.00 | 75.00 | 105.00 | 139.00 | 4–15 |

| 1" (25) | 25 | 79.20 | 90.00 | 85.00 | 125.00 | 160.40 | 4–19 |

| 1-1/4" (32) | 32 | 89.00 | 100.00 | 100.00 | 140.00 | 186.00 | 4–19 |

| 1-1/2" (40) | 40 | 98.00 | 105.00 | 110.00 | 150.00 | 201.00 | 4–19 |

| 2" (50) | 50 | 121.00 | 120.00 | 125.00 | 165.00 | 219.00 | 4–19 |

Feature

Material List

|

S/N | Part | Specification | Qty. |

|---|---|---|---|---|

| 47 | Gasket | EPDM/VITON | 1 | |

| 45 | O-ring | EPDM/VITON | 1 | |

| 34 | Nut | SUS304/SUS316 | 1 | |

| 32 | Washer | SUS304/SUS316 | 8–12 | |

| 30 | Bolt | SUS304/SUS316 | 8–12 | |

| 26 | Buckle | UPVC/CPVC/PPH/PVDF | 8–12 | |

| 03 | Disc | PVDF | 2 | |

| 02 | Upper body | UPVC/CPVC/PPH/PVDF | 1 | |

| 01 | Lower body | UPVC/CPVC/PPH/PVDF | 1 |

| Size | d | d1 | d2 | D | L | L1 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ANSI | DIN | JIS | CNS | ANSI | DIN | JIS | CNS | |||||

| 2-1/2" (65) | 63 | 73.38 | 75.30 | 76.60 | 76.70 | 72.85 | 75.10 | 75.87 | 75.90 | 168.00 | 204.00 | 47.00 |

| 3" (80) | 75 | 89.31 | 90.40 | 89.60 | 89.70 | 88.70 | 90.10 | 88.83 | 88.90 | 172.00 | 230.00 | 53.00 |

| 4" (100) | 95 | 114.76 | 110.40 | 114.70 | 115.00 | 114.10 | 110.10 | 113.98 | 113.80 | 205.00 | 274.00 | 62.00 |

| 6" (150) | 150 | 168.83 | 160.50 | 166.20 | 166.20 | 168.00 | 160.20 | 165.30 | 164.60 | 290.00 | 390.00 | 86.50 |

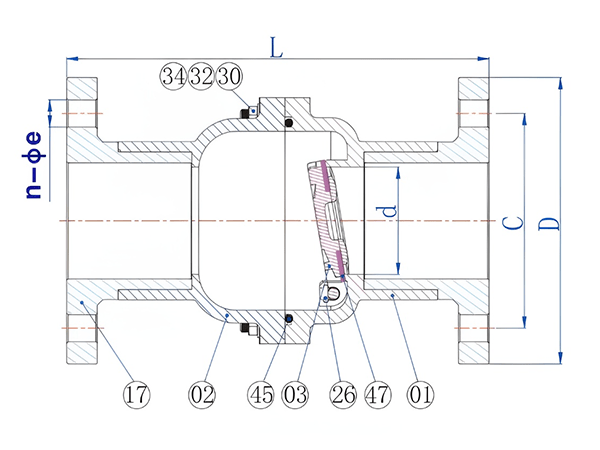

Feature

Material List

2-1/2" – 4"

5" Ref.

6" Ref.

8" Ref.

| S/N | Part | Specification | Qty. |

|---|---|---|---|

| 47 | Gasket | EPDM/VITON | 1 |

| 45 | O-ring | EPDM/VITON | 1 |

| 34 | Nut | SUS304/SUS316 | 8–12 (2.5"–6") 12 (8") |

| 32 | Washer | SUS304/SUS316 | 8–12 (2.5"–6") 12 (8") |

| 30 | Bolt | SUS304/SUS316 | 8–12 (2.5"–6") 12 (8") |

| 26 | Buckle | UPVC/CPVC | 2 |

| 17 | Flange | UPVC/CPVC/PPH/PVDF | 2 |

| 03 | Disc | PVDF | 1 |

| 02 | Upper body | UPVC/CPVC | 1 |

| 01 | Lower body | UPVC/CPVC | 1 |

| Size | d | D | L | C | n-φe | |||

|---|---|---|---|---|---|---|---|---|

| ANSI | JIS | DIN | ANSI | DIN/JIS | ||||

| 2-1/2" | 63 | 182.00 | 280.00 | 139.50 | 140.00 | 145.00 | 4–19 | |

| 3" | 75 | 200.00 | 304.00 | 152.40 | 150.00 | 160.00 | 4–19 | 8–19 |

| 4" | 95 | 228.00 | 356.00 | 190.50 | 175.00 | 180.00 | 8–19 | |

| Remark: If you need van stone, please contact sales. | ||||||||

| Size | d | D | L | C | n-φe | ||||

|---|---|---|---|---|---|---|---|---|---|

| ANSI | DIN/JIS | ANSI/DIN/JIS | ANSI | JIS | DIN | ANSI | DIN/JIS | ||

| 5" | 95 | 256.00 | 250.00 | 290.00 | 216.00 | 210.00 | 210.00 | 8–22 | 8–23 |

| 6" | 150 | 285.00 | 285.00 | 566.00 | 241.00 | 240.00 | 240.00 | 8–22 | 8–23 |

| Size | d | D | L | C | n-φe |

|---|---|---|---|---|---|

| 8" | 150 | 343.00 | 422.00 | 298.00 | 8–23 |

KCV series check valve opens and closes the valve disc through the flow of the medium itself. The medium flows in the specified direction, and when the flow pressure exceeds the opening pressure of the check valve, the valve disc is pushed open by the fluid pressure, thereby allowing the flow of the medium in the pipeline. Conversely, when the medium in the pipeline flows back, the valve disc is pressed against the body of the check valve by the fluid pressure, closing the valve and thus cutting off the flow of the medium in the pipeline. Moreover, the greater the pressure of the backflow medium, the tighter the valve disc closes, resulting in a better sealing effect.

KCV Series Check Valve Working Principle

Here are product catalogue and data sheet for your reference. more information just contact us.