Check whether the groove meets the standard before installation.

Remove the burrs, rust, oil, paint and other impurities on the tube and sealing ring. Pipe ends must be clean and smooth, free from unevenness.

In piping systems, the use of grooved couplings has become increasingly popular due to their numerous advantages. Grooved couplings provide a reliable and flexible connection between grooved pipes, allowing for easy installation, maintenance, and accommodating for movements and misalignments. Whether you’re working on a plumbing project or an industrial application, understanding how to properly install grooved couplings is essential. In this article, we will provide you with a step-by-step guide that covers the key aspects of installing grooved couplings, ensuring a secure and efficient piping system.

Here is a step by step guide diaphragm: ( View Video)

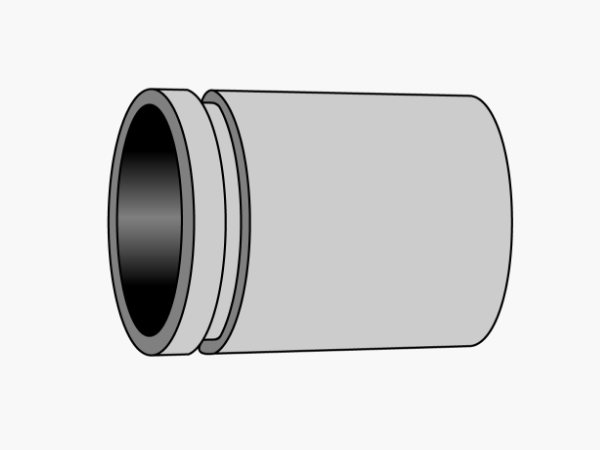

Check whether the groove meets the standard before installation.

Remove the burrs, rust, oil, paint and other impurities on the tube and sealing ring. Pipe ends must be clean and smooth, free from unevenness.

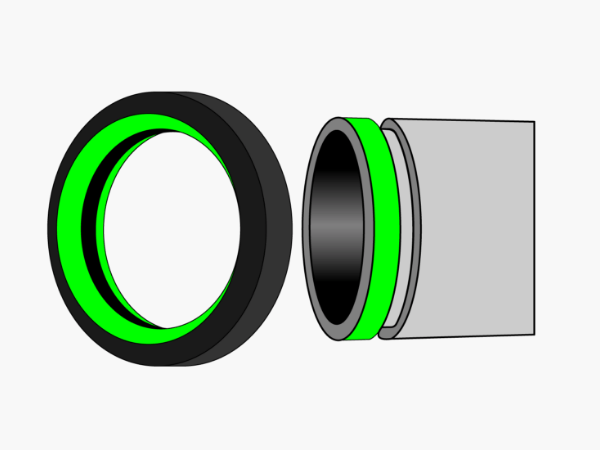

Apply silicone lubricant to the end of pipe, outer surface of rubber ring and sealing lip, and do not use petroleum-based lubricant.

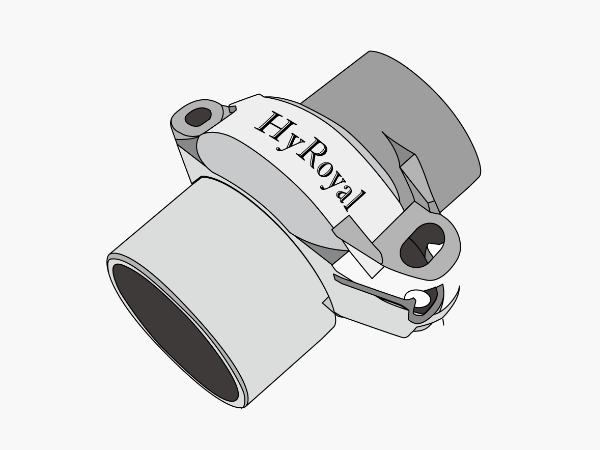

Install the rubber sealing ring into the sealing part of a steel pipe.

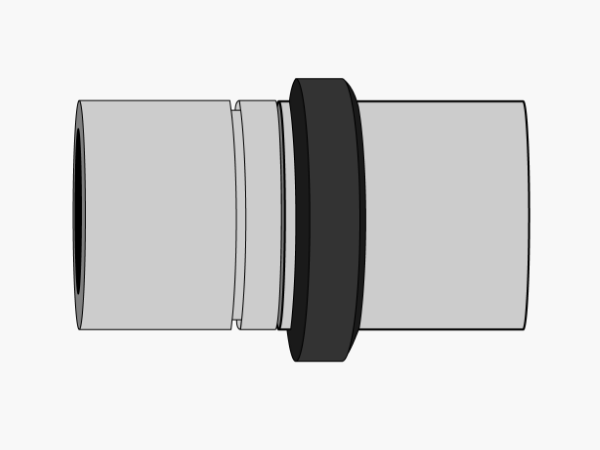

Align the two steel pipes.

After the two steel pipes are aligned, pull back the rubber ring to the center of the pipe end, so that the rubber ring is just located at the sealing part outside the groove, and ensure that the rubber ring stretches naturally without distortion.

Make sure that the grooved couplings are aligned with the grooves on both sides.

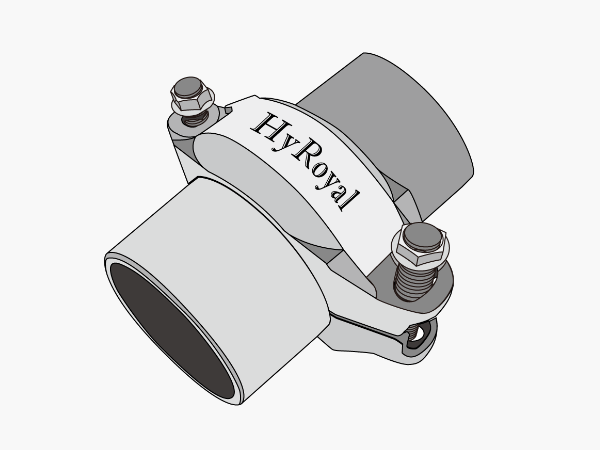

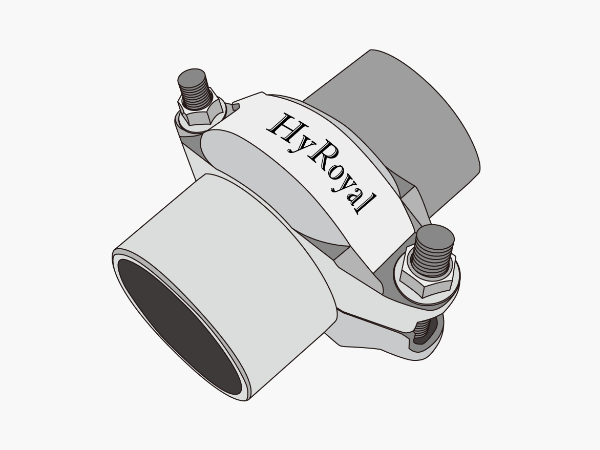

Thread the bolts and nuts.

Tighten the nuts evenly from both sides with a torque wrench until the pipe clamp is tightly fastened to the pipe. The gap at the rigid joint must be equal on both sides, and there is no gap at the grooved joint. Rubber rings should not be seen from the outside of rigid and grooved joint.

Precautions

Description of pressure rating:

*Special note: when used at the outlet of high-pressure pumps and plunger pumps, models with one grade higher than the operating pressure must be selected.

(For example: If the actual pressure at the pump outlet is 1200 psi (S80), it is recommended to choose the clamp of the S160 series)

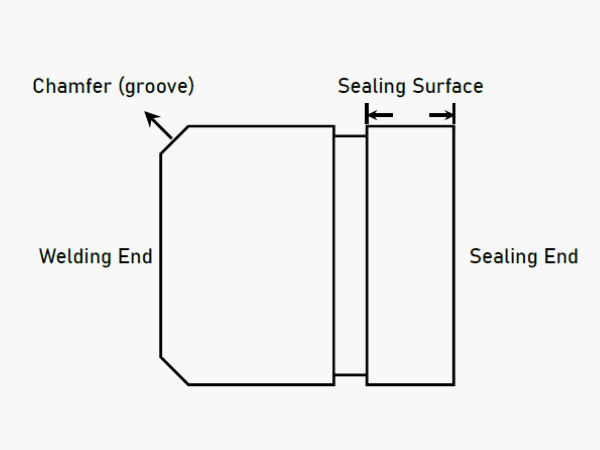

Notes on installation of grooved short pipes

Grooved pipes structure

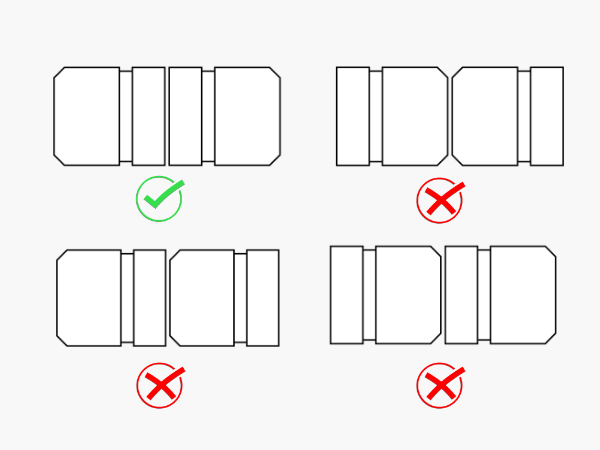

Correct and Three Error View

| Thread | Breaking Torque (Nm) | ||

|---|---|---|---|

| Performance Level | |||

| 50 | 70 | 80 | |

| M1.6 | 0.15 | 0.2 | 0.24 |

| M2 | 0.3 | 0.4 | 0.48 |

| M2.5 | 0.6 | 0.9 | 0.96 |

| M3 | 1.1 | 1.6 | 1.8 |

| M4 | 2.7 | 3.8 | 4.3 |

| M5 | 5.5 | 7.8 | 8.8 |

| M6 | 9.3 | 13 | 15 |

| M8 | 23 | 32 | 37 |

| M10 | 46 | 65 | 74 |

| M12 | 80 | 110 | 130 |

| M16 | 210 | 290 | 330 |