The RO membrane is installed in the same way as NF membrane.

Before loading, make sure safety shoes, rubber gloves, safety glasses, pliers, silicone lubricant, clean rags, and glycerin are well-prepared.

1

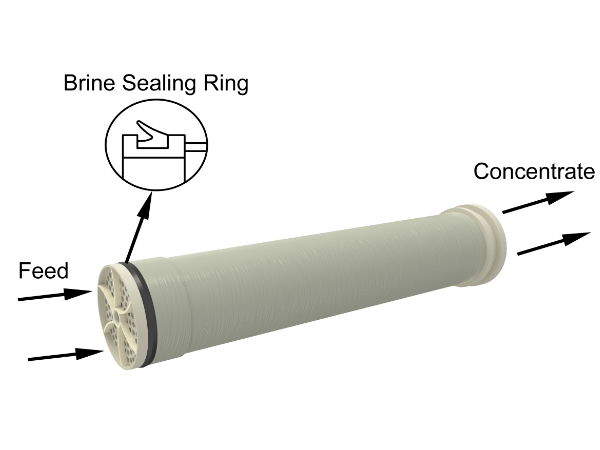

Take out the membrane elements carefully from the packing box. Check if the position and direction of the brine sealing ring on the membrane element are correct. It should be noted that the open section of the brine sealing ring shall be placed towards the feed water direction.

2

Place the end of NF membrane element without the brine seal ring horizontally into the feed water end of the pressure vessel and push the element until about 10 cm of the element length is exposed outside the feed water end of the pressure vessel. It should be noted that always load membrane elements into the feed water end of the pressure vessel.

3

Install the interconnector into the permeate tube of the element. Before installing the interconnector, lubricate the o-ring seals on the interconnector with silicon lubricate, glycerin or qualified pre-treated water to facilitate the interconnector installation.

4

Take out the 2nd membrane elements carefully from the packing box. Check if the position and direction of the brine sealing ring on the 2nd element are correct. Hold the 2nd element carefully and make the interconnector on the 1st element insert into the the permeate tube of the 2nd element. Slide the 2nd element until about 10 cm of the element length is exposed outside the the feed water end of the pressure vessel. Push the 2nd element into the pressure vessel and hold it carefully so that the weight is not supported by the interconnector.

5

Repeat step 3 and step 4 until all elements are loaded into the pressure vessel. And then turn to the concentrate end and install the thrust cone into the concentrate end of the 1st element.

6

Check the O-ring on the adaptor connected with the membrane element carefully. Insert the end of the adaptor without the O-ring into the end plate (sealing board, sealboard rubber O-ring, pressure head) and secure with fastening nuts. Insert the end of the adaptor with the O-ring into the permeate tube of the element. Place the stopper around the pressure head, install the retaining ring on the stopper and secure the stopper with stop screws.

7

Install the end plate on the feed water end the same way as install the concentrate end (without the thrust cone installation procedure). And then install the inlet plug.

8

Repeat these steps, load NF membrane elements into every pressure vessel and connect all external feed water, concentrate and permeate pipes.