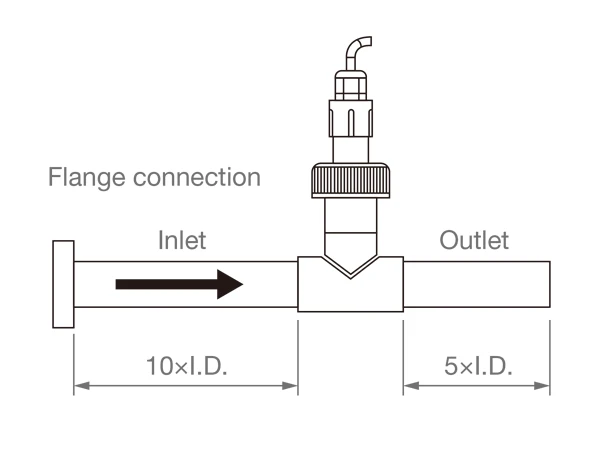

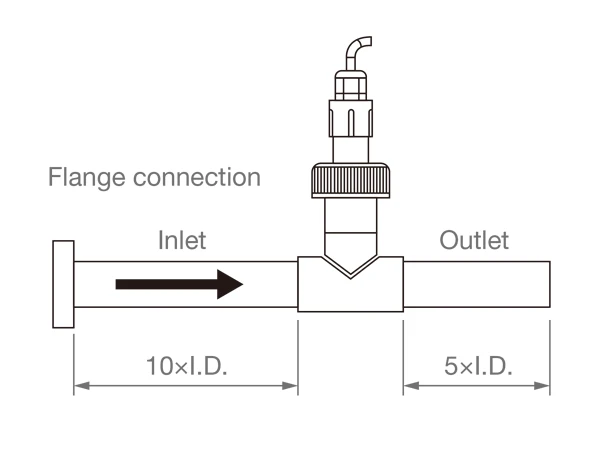

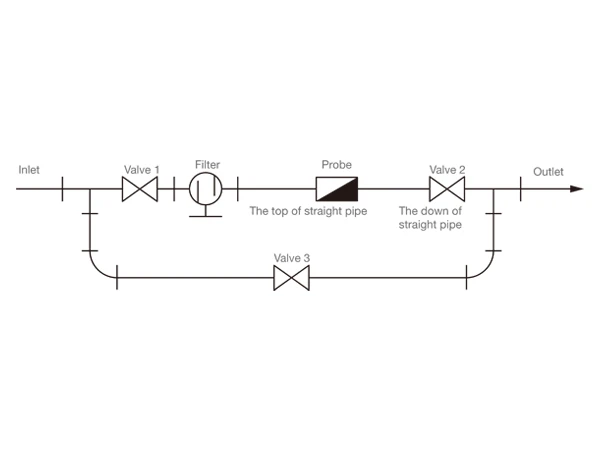

Connection in a straight pipe

Proper installation of a wheel flow sensor is crucial for achieving reliable and accurate flow measurements in fluid systems. Improper installation can lead to significant errors in data collection, impacting the overall efficiency and safety of the system. It is essential to follow guidelines regarding sensor location, orientation, and environmental considerations to prevent interference such as flow blockage and air entrapment. Ensuring that the sensor is installed correctly can maximize equipment performance, reduce maintenance requirements, and extend the sensor's operating life, thereby safeguarding the integrity and reliability of the measurement system.

Precautions before Installation

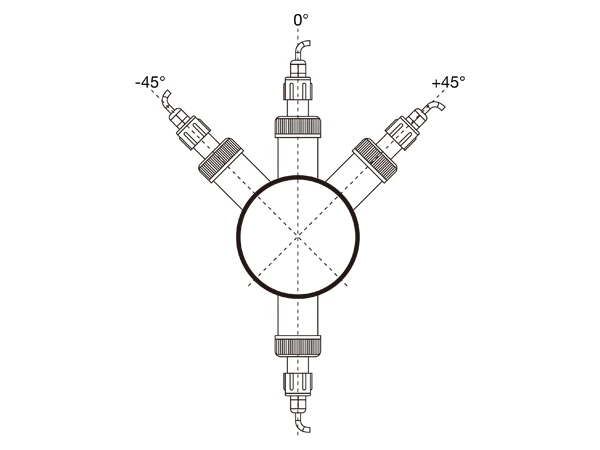

Before installing the flow sensor into the mounting bracket, the front part needs to be immersed in water. Install it in place with the help of the lubrication of water to avoid damaging the "O" ring caused by dry friction, affecting the sealing performance. At the same time, pay special attention to ensure that the two plugs of the sensor are aligned with the grooves of the mounting bracket.

Installation Requirements

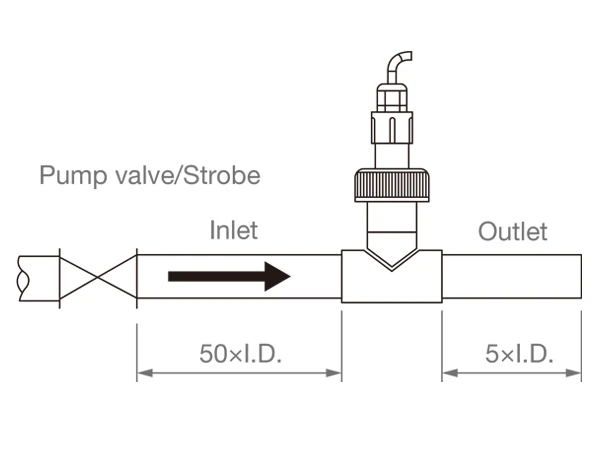

Connection in a straight pipe

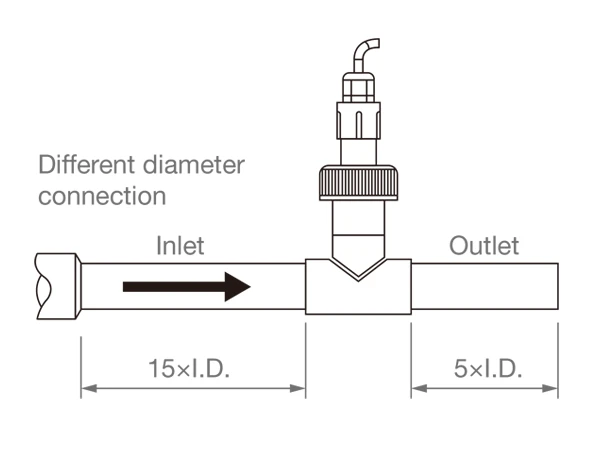

Connection in a reducing pipe

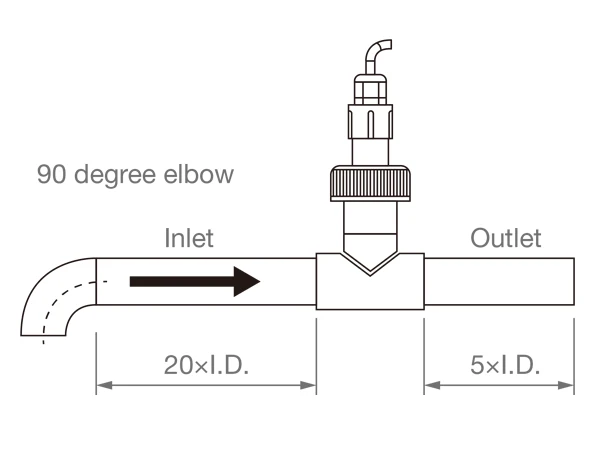

Connection downstream of elbow

Connection downstream of valve

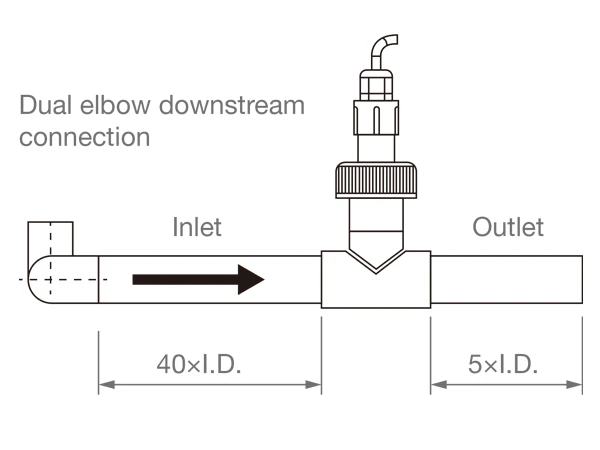

Dual elbow downstream connection

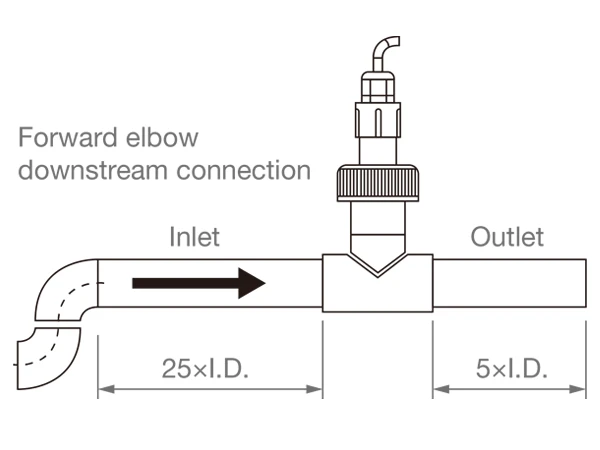

Forward elbow downstream connection

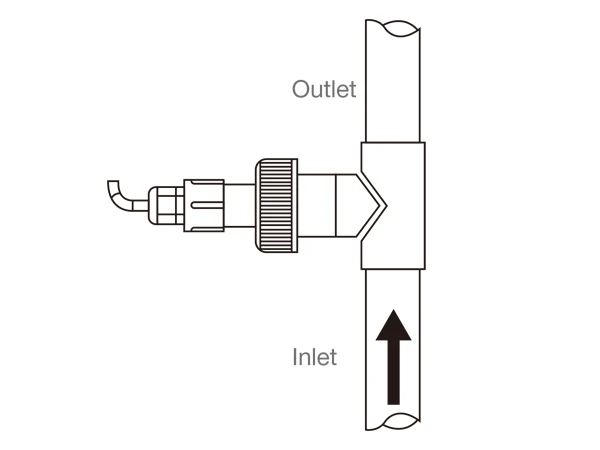

Installation of the pipeline in vertical state

Installation when some impurities in the pipeline

The connection of level of the pipeline when there are bubbles

The above are the installation methods of the sensor under different pipeline conditions, which can be used as a reference. If you encounter any problems during the sensor installation, you can contact us at any time.