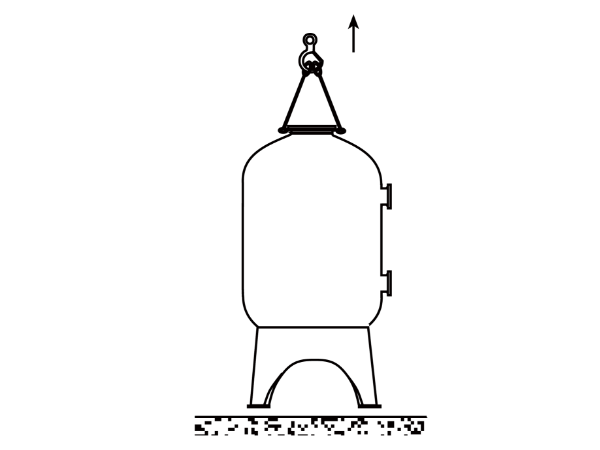

Method 1: Hoist with tank flanges Empty FRP tanks can be hoisted with flanges on the tank body. It should prepare hoisting device or cable in advance.

For 21" FRP Tanks Loading

FRP tanks with a diameter of 21" and below shall be handled manually. Please handle with care to prevent falling and collision.

For 24" FRP Tanks Loading

FRP tanks with a diameter of 24" and above shall be handled with a forklift or a crane. If the FRP tank upper port is provided with a flange, it can be handled by hoisting. If the FRP tank upper port is not provided with a flange, it can be handled with a forklift.

Method 1: Hoist with tank flanges Empty FRP tanks can be hoisted with flanges on the tank body. It should prepare hoisting device or cable in advance.

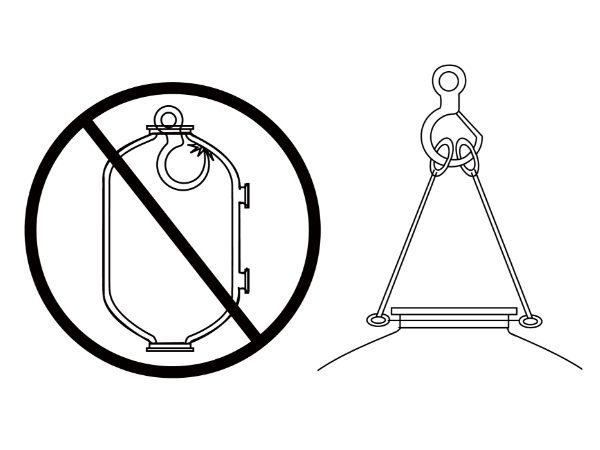

Method 2: Hoist with a strap Prepare a 1/2" steel strap to connect with flanges and every side requires at least 2 bolts. Hook and steel cable need to lift at least 10,000 pounds (4,500 kg).

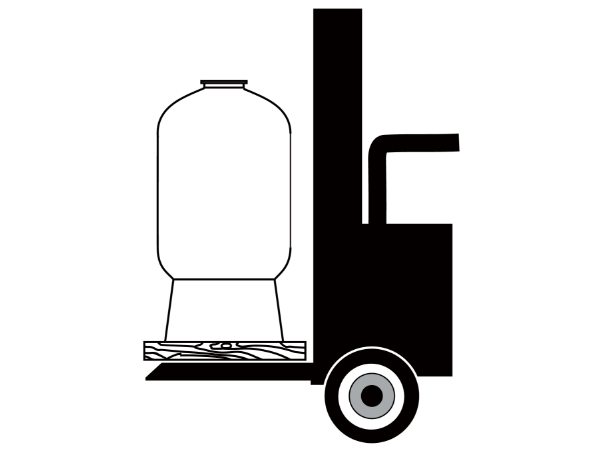

Method 3: Handle with a forklift Use a forklift to lift and handle FRP tanks.

For 40" FRP Tanks Installation

Hoist Hoist the FRP tanks in the same way of hoisting FRP tanks with a diameter of 24" and above and remove the outer package.

Fix the FRP tank After installing the tanks and filling materials, the FRP tanks should be fixed on the ground with pressing plate and expansion bolts.

Precautions

Wear a pair of rubber gloves when handling or installing FRP tanks;

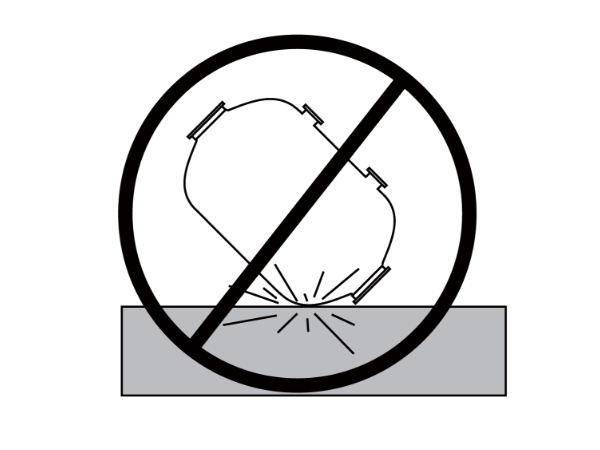

Do not roll or slide the FRP tank;

Do not drop or knock against FRP tank. Do not allow the FRP tank collide with wall or other equipment;

Use a forklift or a crane to hoist the FRP tank; compliant hoisting procedures must be followed;

Do not use hook to lift the FRP tank from inside. You may lift the FRP tank from the outside flanges, so that the inner lining is not damaged;

Do not use steel wire or chain to fix FRP tank. You may use canvas bag or nylon to prevent FRP tank from slipping off.